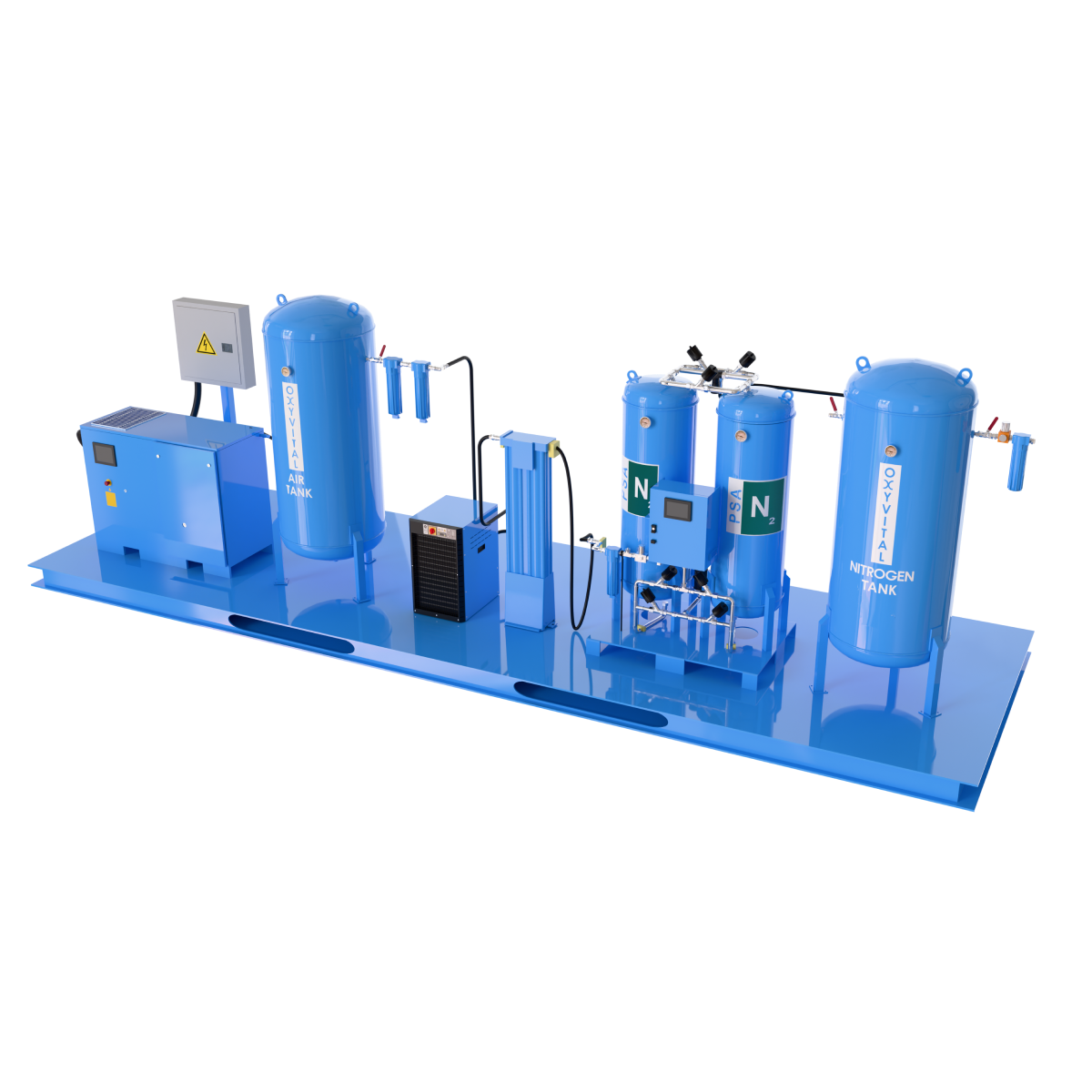

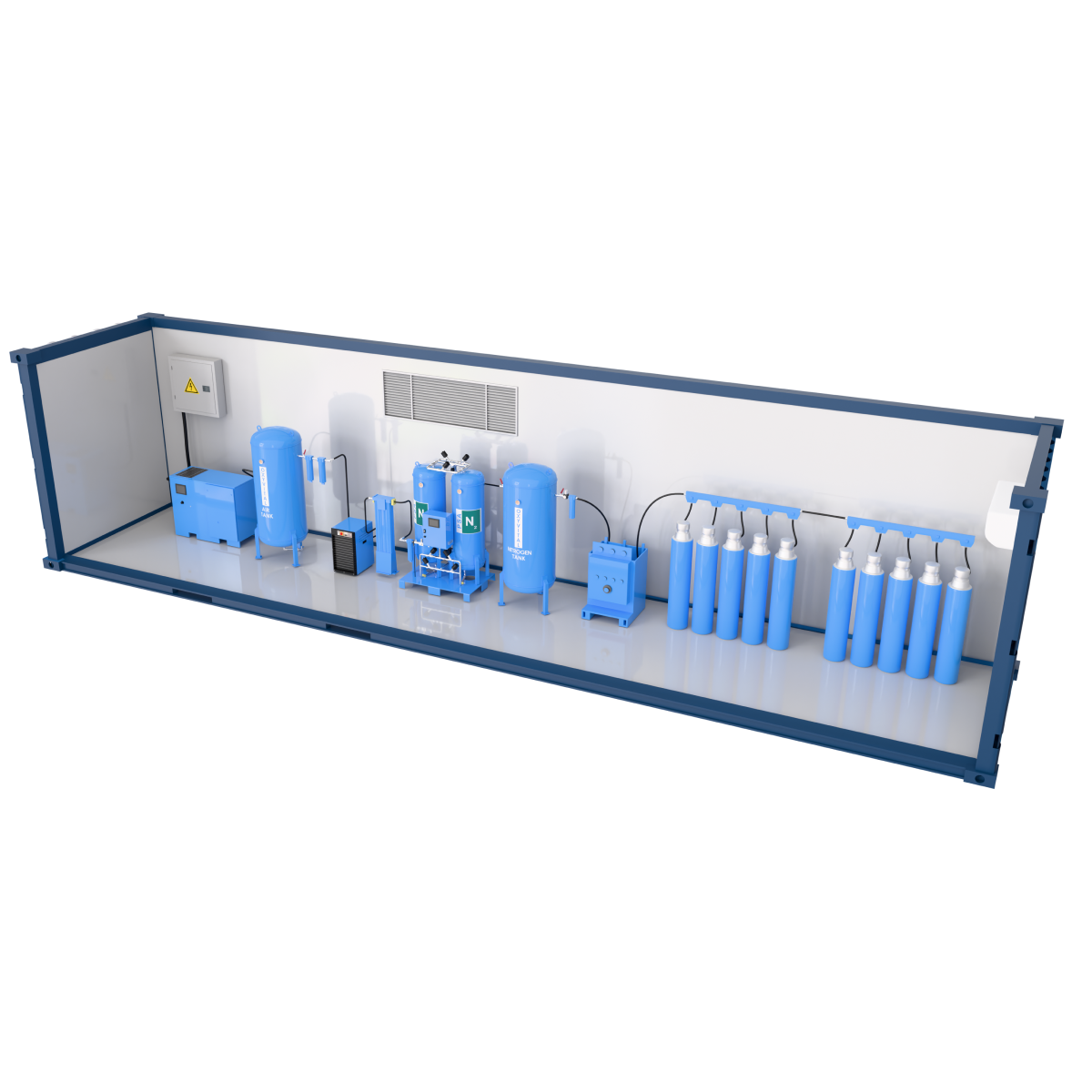

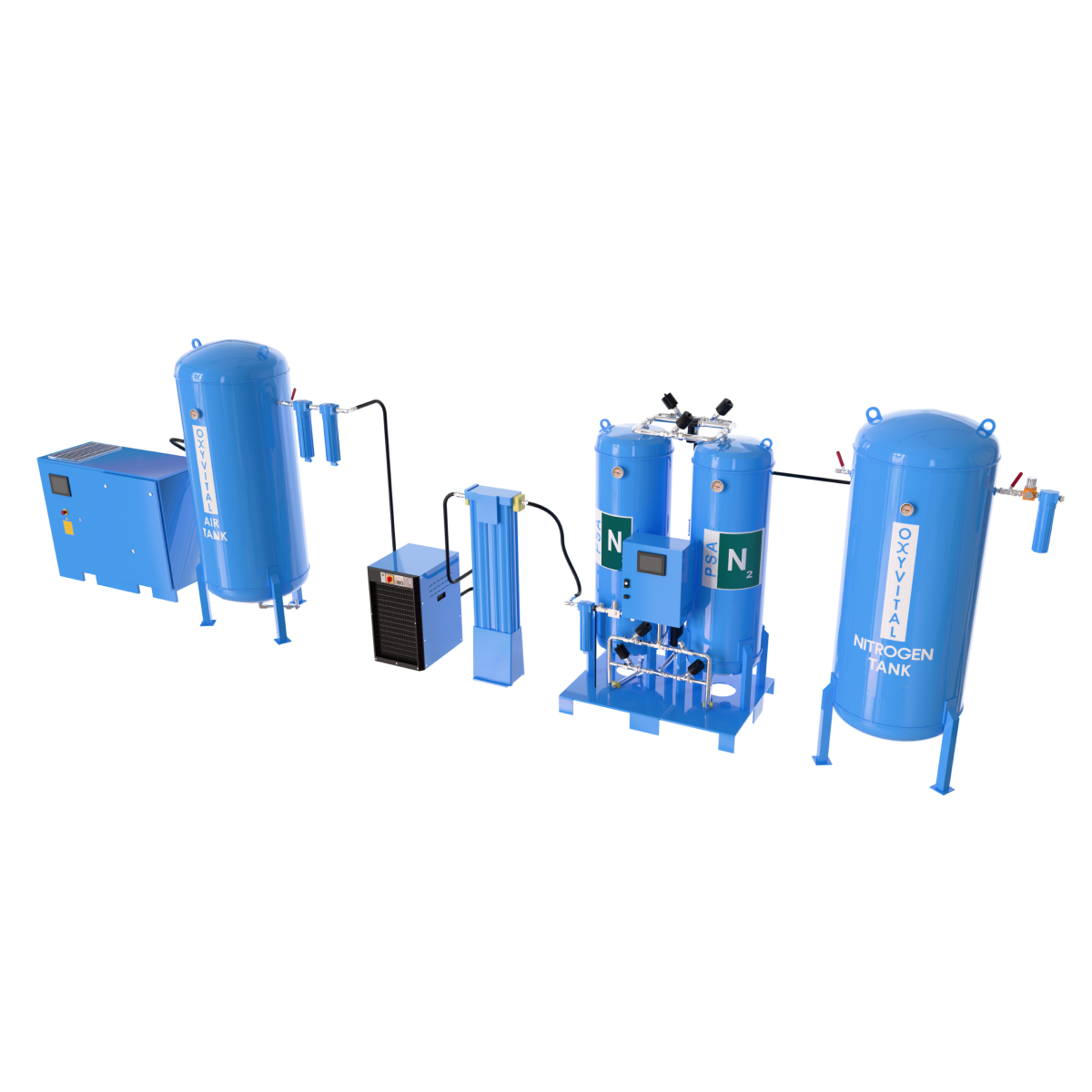

Use of OXYVITAL PSA Nitrogen Generators in Laser and Plasma Cutting

In laser and plasma cutting processes, nitrogen (N₂) plays a crucial role in achieving high-quality cutting surfaces, preventing oxidation, and increasing cutting speed. OXYVITAL PSA Nitrogen Generators provide a continuous supply of high-purity nitrogen, enhancing operational efficiency and reducing costs in these industrial cutting applications.

Applications of PSA Nitrogen Generators in Laser and Plasma Cutting

1. Use of Nitrogen in Laser Cutting

Inert nitrogen is used to prevent oxidation when laser-cutting stainless steel, aluminum, carbon steel, and other metals.

Nitrogen prevents molten metal from reacting with the surface, resulting in clean and smooth cuts.

Produces brighter and higher-quality surfaces, reducing the need for post-grinding or polishing.

2. Use of Nitrogen in Plasma Cutting

High-pressure nitrogen improves arc stability in plasma cutting torches, enabling faster and more precise cuts.

In stainless steel and aluminum cutting, nitrogen minimizes oxidation and produces burr-free edges.

Reduces smoke and contamination during cutting, ensuring a cleaner working environment.

3. Advantages of Using Nitrogen in Metal Cutting

High-purity nitrogen prevents burn marks and discoloration on metal surfaces.

Operates with lower thermal impact, reducing heat-related deformations.

In steel cutting, nitrogen achieves cleaner edges and reduces material waste compared to CO₂ laser systems.

4. Continuous and Reliable Nitrogen Supply

PSA generators deliver a constant stream of high-purity nitrogen, eliminating dependence on gas cylinders.

Provide uninterrupted and economical gas supply for laser and plasma cutting machines.

Offer an efficient, sustainable, and cost-effective solution for large-scale manufacturing facilities.

Advantages of OXYVITAL PSA Nitrogen Generators in Laser and Plasma Cutting

Prevent oxidation during cutting, ensuring cleaner and higher-quality surfaces.

Supply continuous nitrogen at a lower cost compared to CO₂ and other gas systems.

Provide high-pressure, uninterrupted nitrogen flow, boosting the efficiency of plasma and laser cutting machines.

Eliminate burn marks and discoloration caused by oxygen, producing bright and smooth edges.

Remove dependency on gas cylinders, lowering operational costs and simplifying logistics.

OXYVITAL PSA Nitrogen Generators are the ideal solution for achieving high performance, cost efficiency, and a sustainable gas supply in laser and plasma cutting operations.