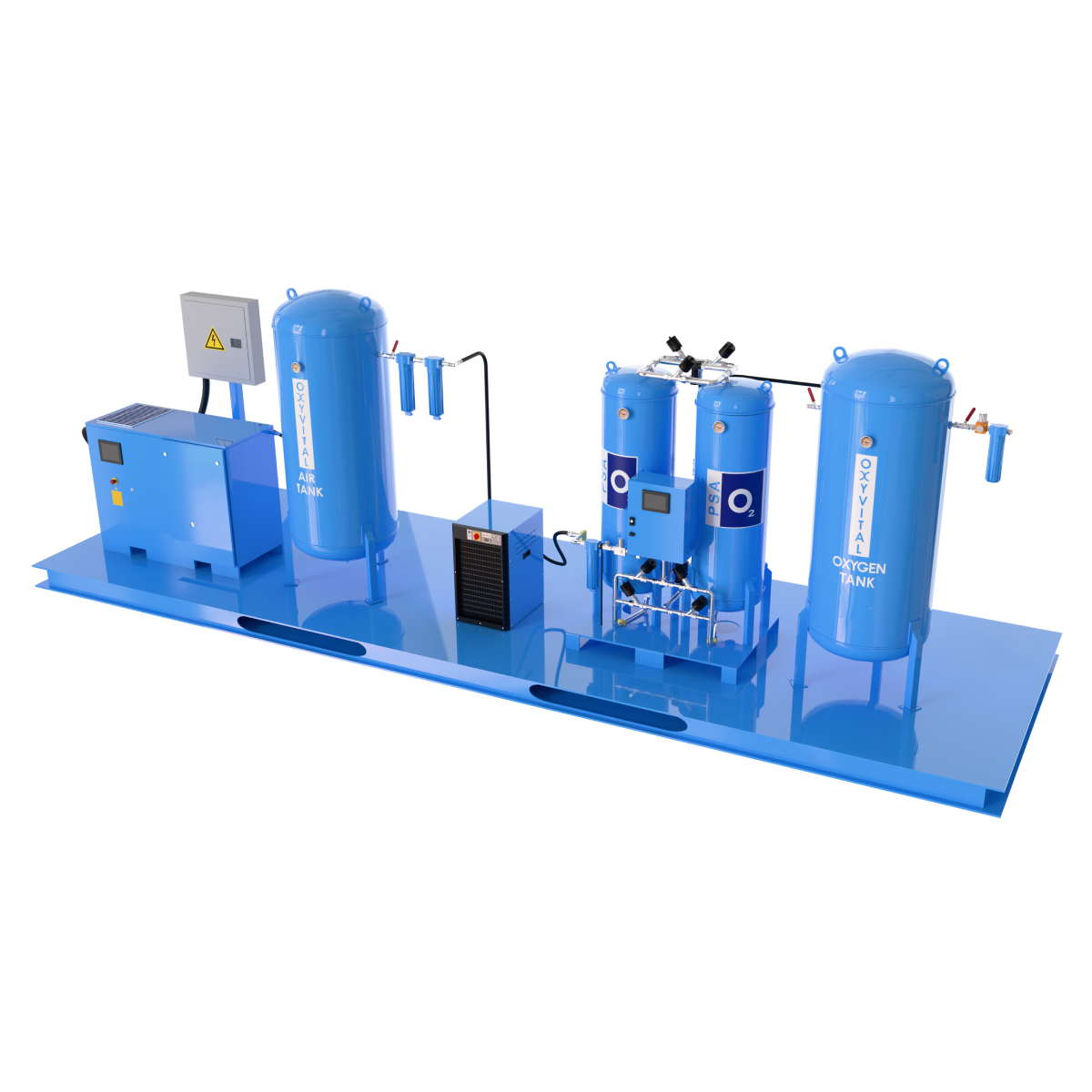

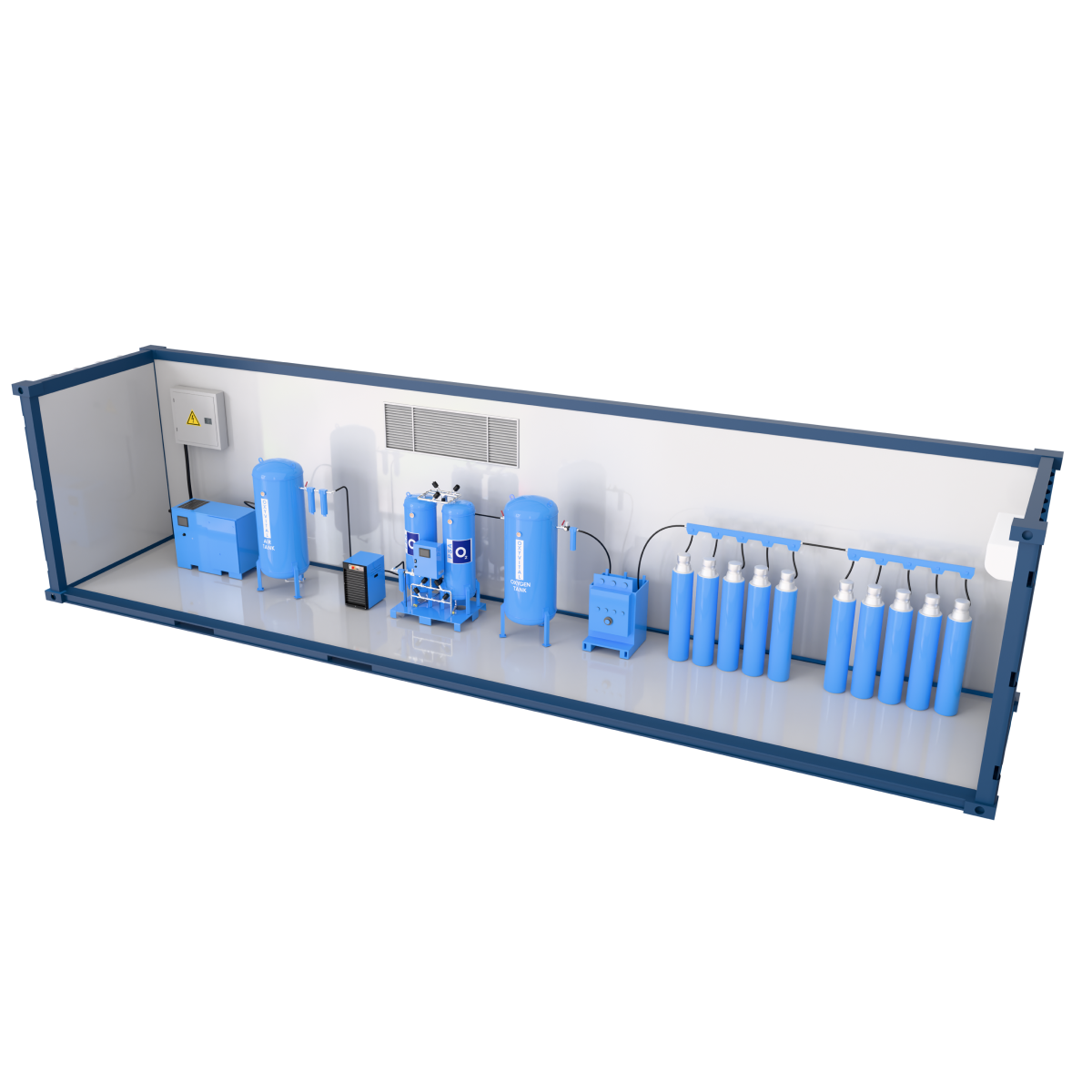

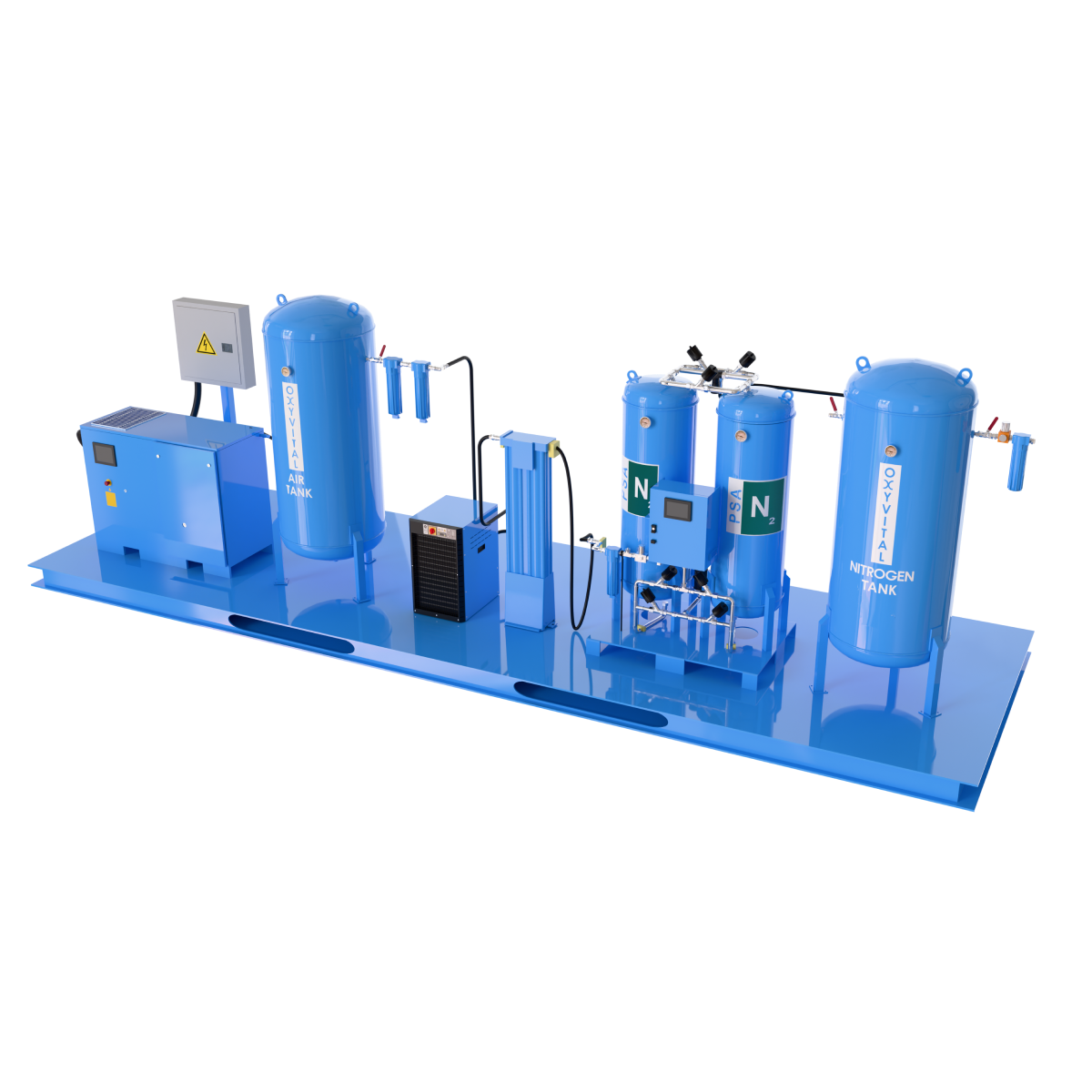

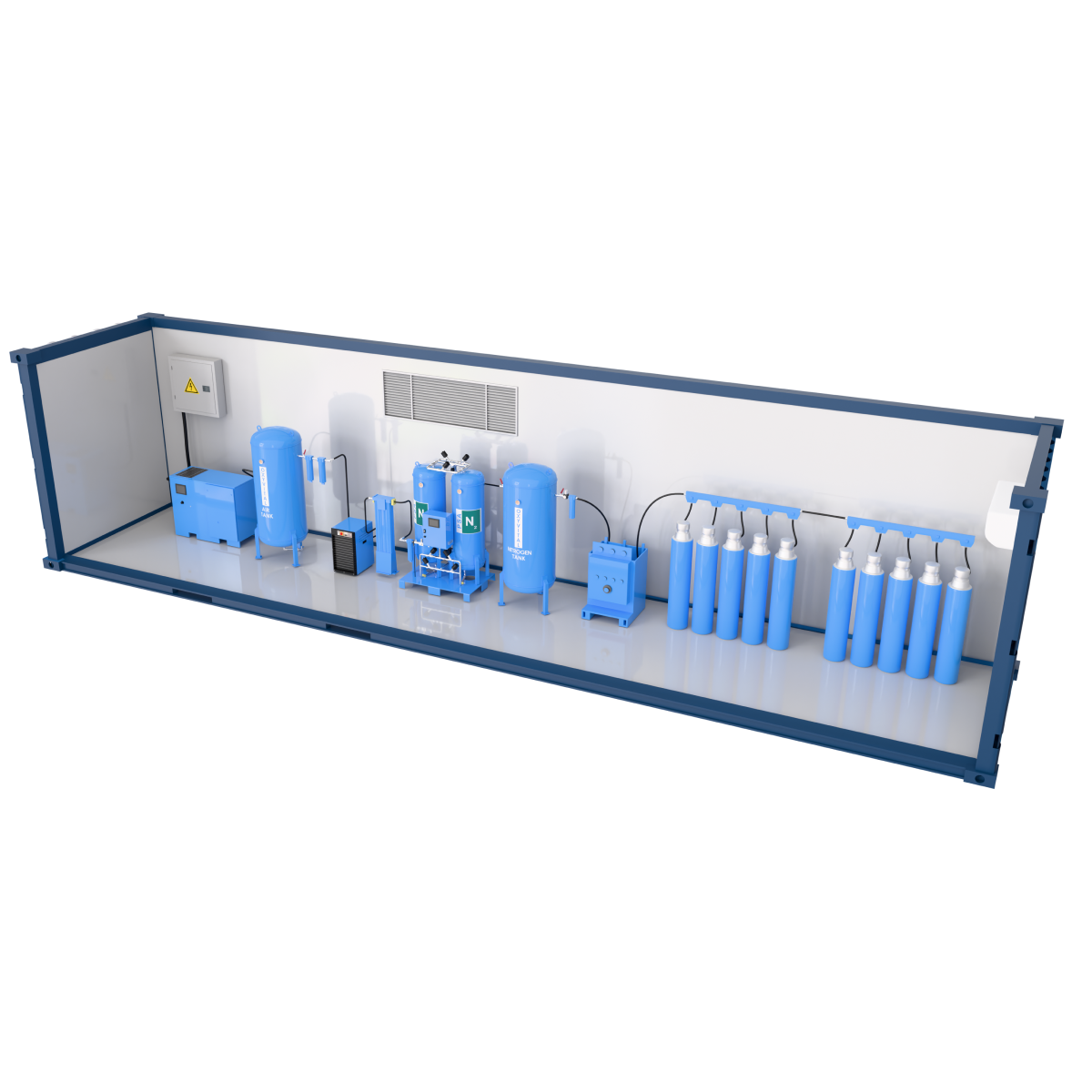

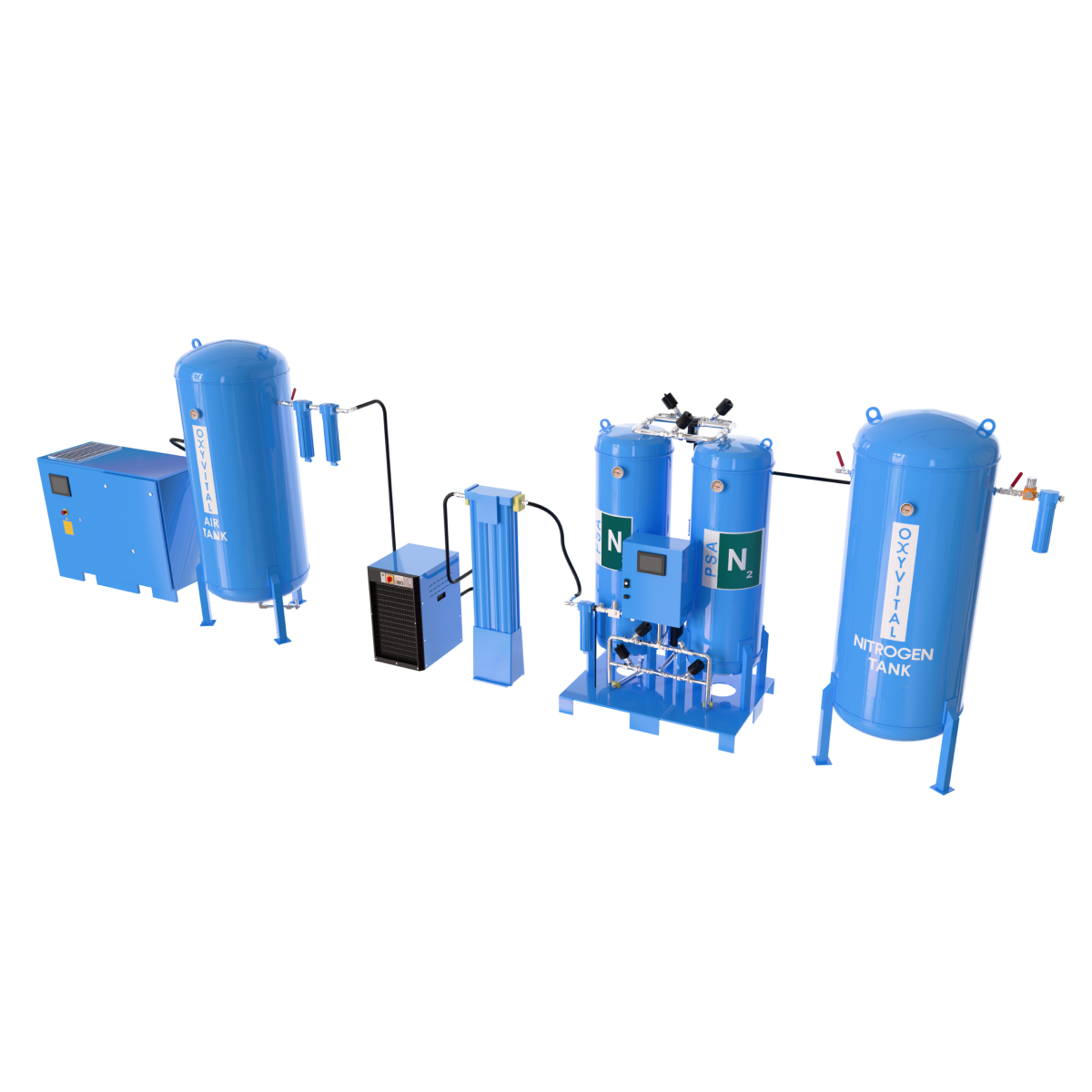

Use of OXYVITAL PSA Nitrogen Generators in Modified Atmosphere Packaging (MAP) Systems

Use of OXYVITAL PSA Nitrogen Generators in Modified Atmosphere Packaging (MAP) Systems

Modified Atmosphere Packaging (MAP) is a technology that extends shelf life, preserves freshness, and prevents microbial growth in food products by using special gas mixtures.

In these systems, OXYVITAL PSA Nitrogen Generators create an inert atmosphere by controlling the oxygen level inside the package. This prevents spoilage, maintains the quality of oxygen-sensitive foods, and helps keep products fresh for longer periods.

Applications of Nitrogen in MAP Systems

1. Snack Foods and Nuts Packaging

Prevents staleness by eliminating oxygen contact in products such as chips, nuts, coffee, chocolate, and biscuits.

Avoids oxidation in high-fat products, protecting taste and aroma.

Maintains package volume, creating a protective atmosphere that prevents product breakage.

2. Meat, Poultry, and Fish Packaging

Reduces oxygen levels, slowing microbial growth and extending shelf life.

Helps preserve the natural color of raw and processed meat products.

When combined with vacuum packaging, allows for longer preservation periods.

3. Dairy Products Packaging

Protects products such as cheese, milk powder, yogurt, and butter by preventing bacterial and mold growth.

In cheese production, supports controlled ripening processes.

4. Bakery Products and Coffee Packaging

Prevents mold formation caused by oxygen in bread, cakes, pasta, and other carbohydrate-based products.

Preserves aroma and flavor in coffee and tea, ensuring longer freshness.

5. Fruits, Vegetables, and Ready Meals Packaging

Optimizes oxygen levels to control ripening in fruits and vegetables.

Helps maintain the taste and texture of ready-to-eat meals.

Advantages of OXYVITAL PSA Nitrogen Generators in MAP Systems

Provides a reliable gas supply with continuous high-purity nitrogen production.

Extends shelf life of food products without the use of chemical preservatives.

Eliminates dependency on oxygen cylinders and liquid nitrogen, reducing logistics and operational costs.

Prevents mold, bacteria, and oxidation by lowering oxygen levels inside the package.

Maintains gas balance within packaging, preventing deformation and product breakage.

Supports sustainable production by offering a more environmentally friendly process.

OXYVITAL PSA Nitrogen Generators are the ideal solution for MAP systems, enabling longer shelf life, higher-quality packaging, and oxidation-free food preservation.