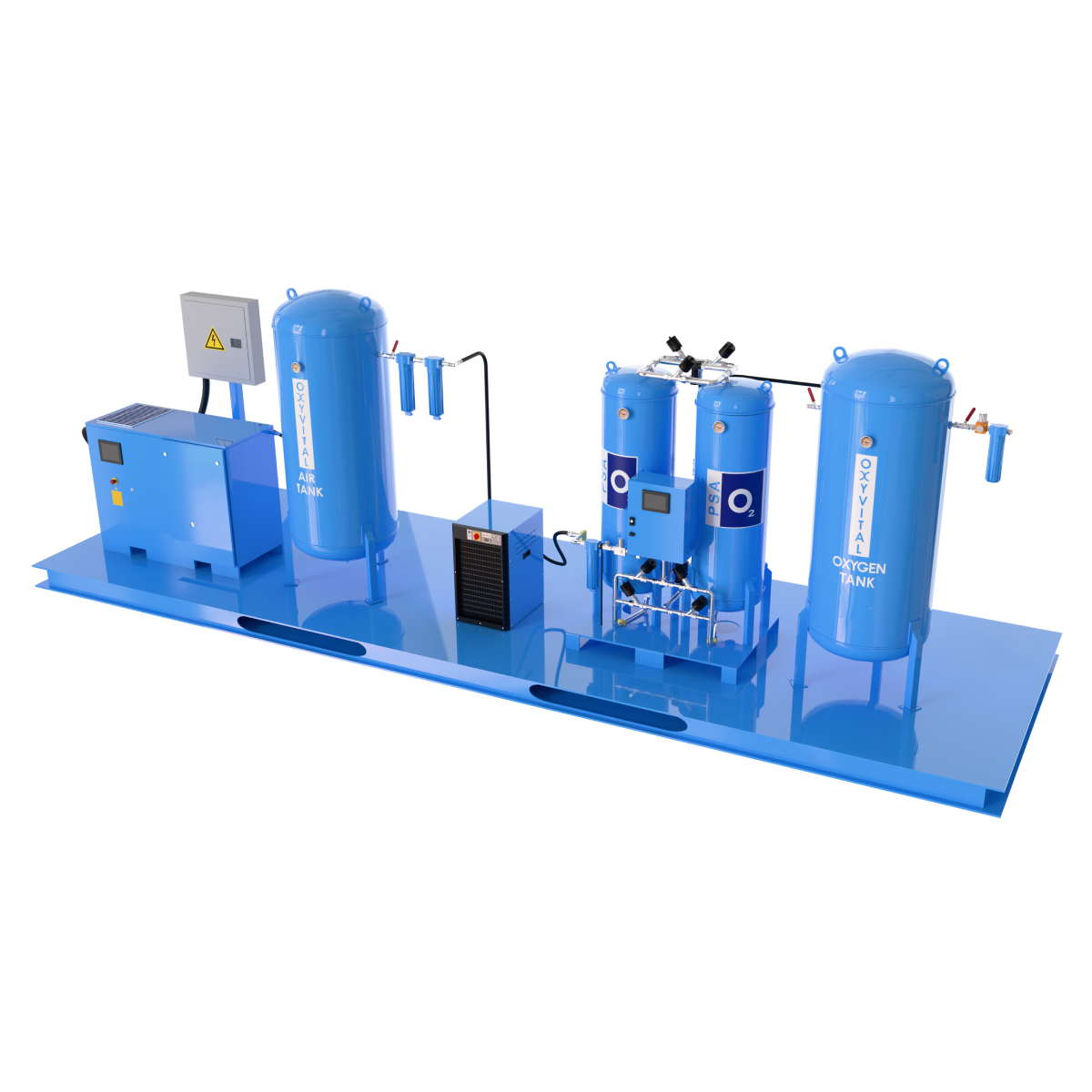

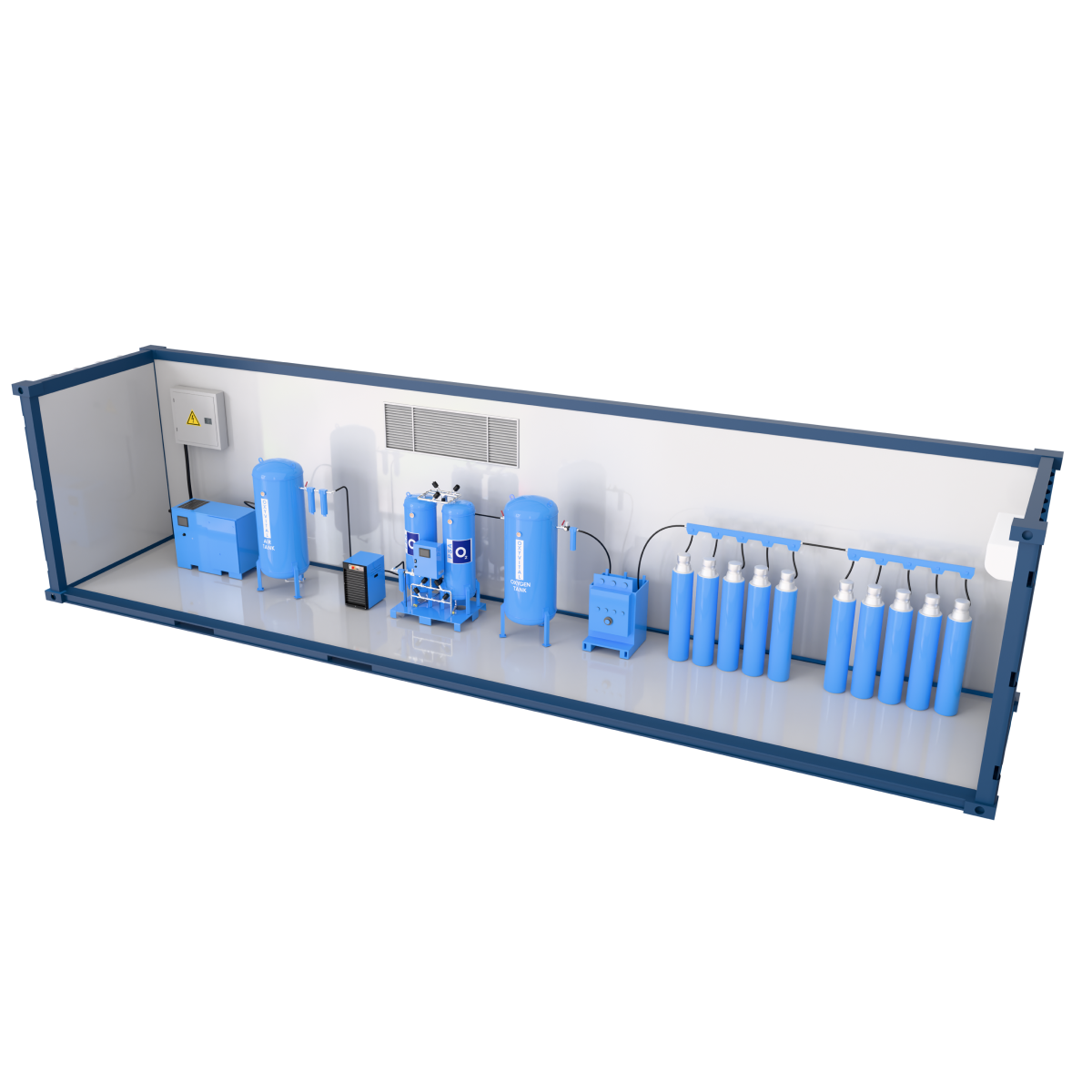

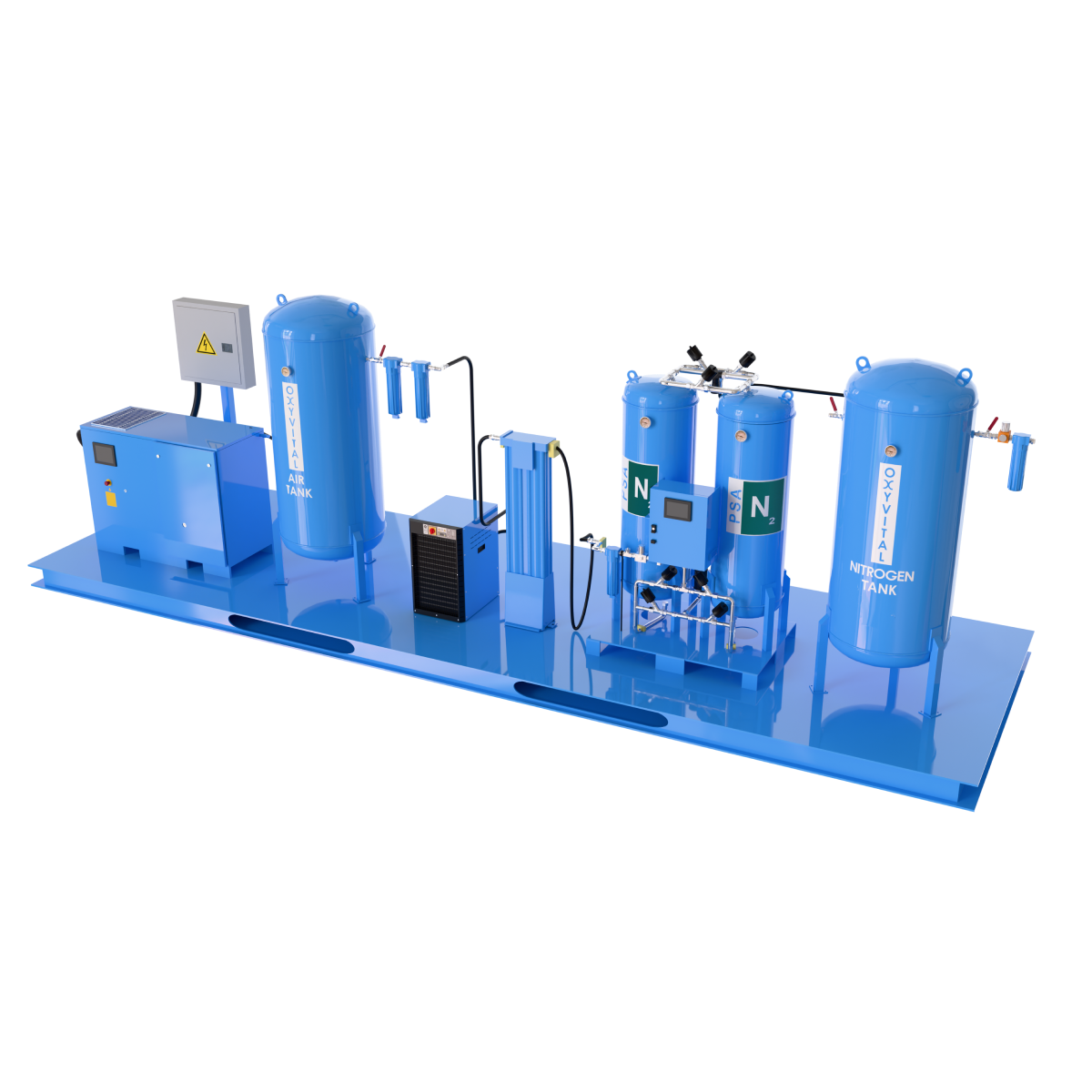

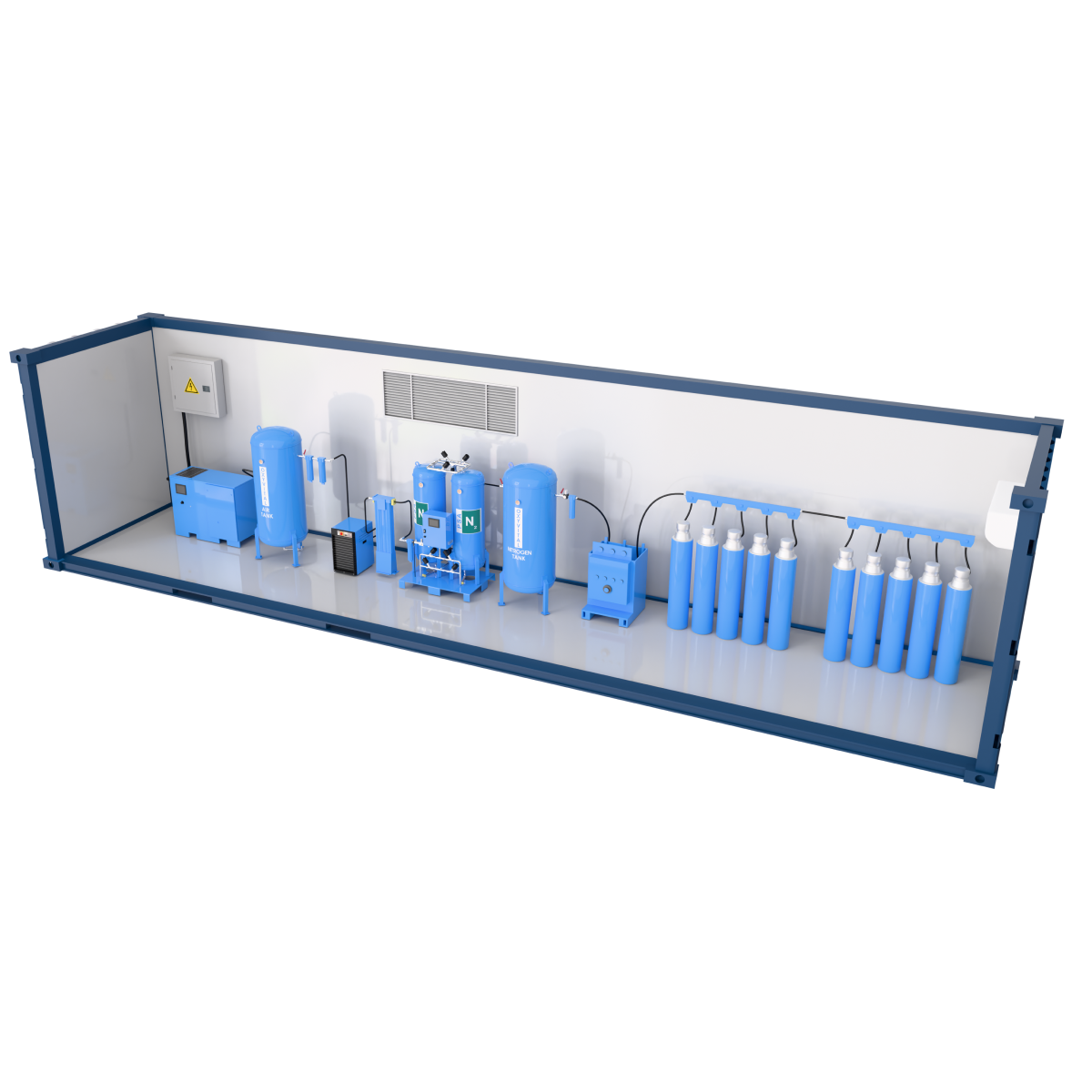

PSA Oxygen Generators in Industry: Metal Cutting and Welding Solutions

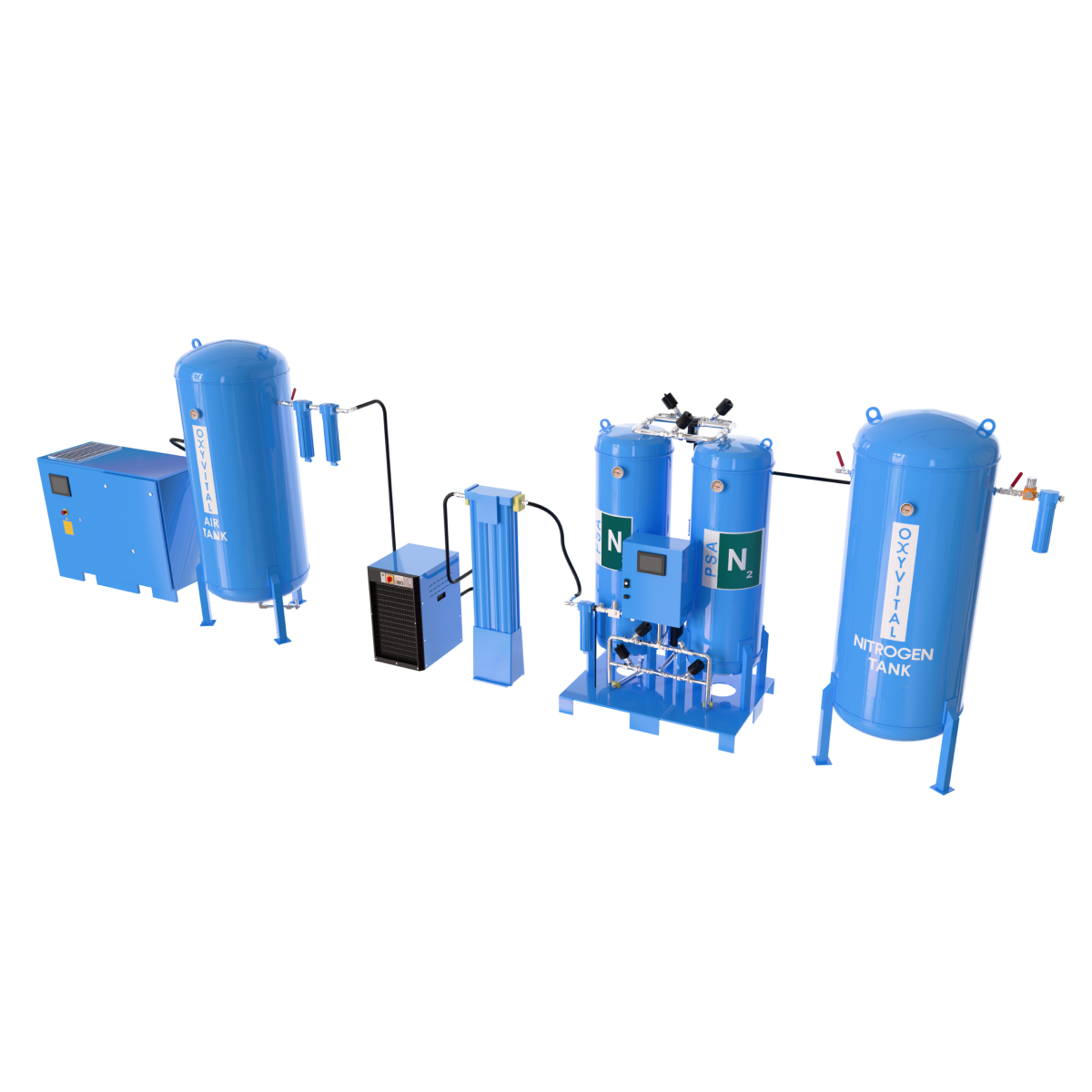

OXYVITAL PSA Oxygen Generators deliver high-purity oxygen for industrial applications, enhancing efficiency in metal cutting and welding operations. Providing a continuous and reliable oxygen source for laser, plasma, and oxy-fuel cutting, these systems ensure cost savings and operational productivity across manufacturing processes.

Advantages of PSA Oxygen Generators for Metal Cutting and Welding

1. Continuous and High-Purity Oxygen Production

Produces oxygen at 93% ±3 purity, ideal for cutting and welding applications.

Eliminates dependency on cylinders and ensures uninterrupted oxygen supply.

2. Cost Reduction and High Savings

Removes expenses related to purchasing cylinders and cryogenic oxygen.

Generates oxygen using only air and electricity, reducing operating costs by up to 50% in the long term.

3. Optimum Solution for Plasma and Oxy-Fuel Cutting

Provides a stable oxygen source for plasma and oxy-fuel cutting machines.

Enables cleaner, smoother, and faster cutting operations.

Improves combustion efficiency, ensuring more precise metal processing.

4. High Efficiency and Eco-Friendly Technology

Eliminates logistics challenges associated with oxygen cylinders, increasing operational flexibility.

Reduces waste gas emissions, offering an environmentally friendly solution.

Applications of PSA Oxygen Generators

Metal Cutting (Plasma, Oxy-Fuel, and Laser Cutting)

Welding Operations (MIG, TIG, and Oxy-Fuel Welding)

Steel Plants and Metal Production Facilities

Glass and Ceramics Manufacturing

Chemical and Petrochemical Industries

Uninterrupted and Cost-Effective Oxygen Supply with OXYVITAL PSA Oxygen Generators!

OXYVITAL’s industrial PSA generators lower costs while improving cutting and welding quality, making them an essential solution for the metalworking industry.