30+

Cylinder Filling Systems

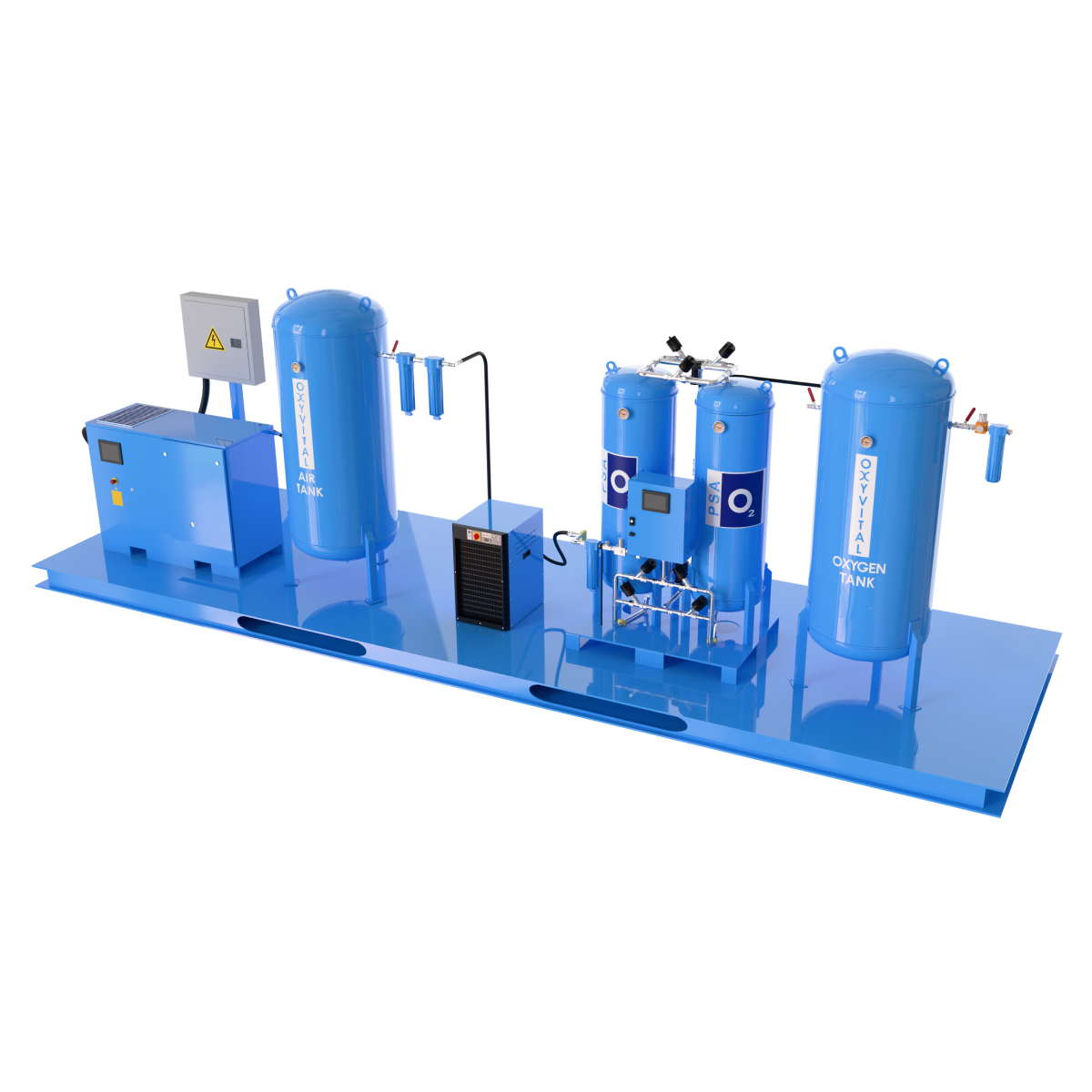

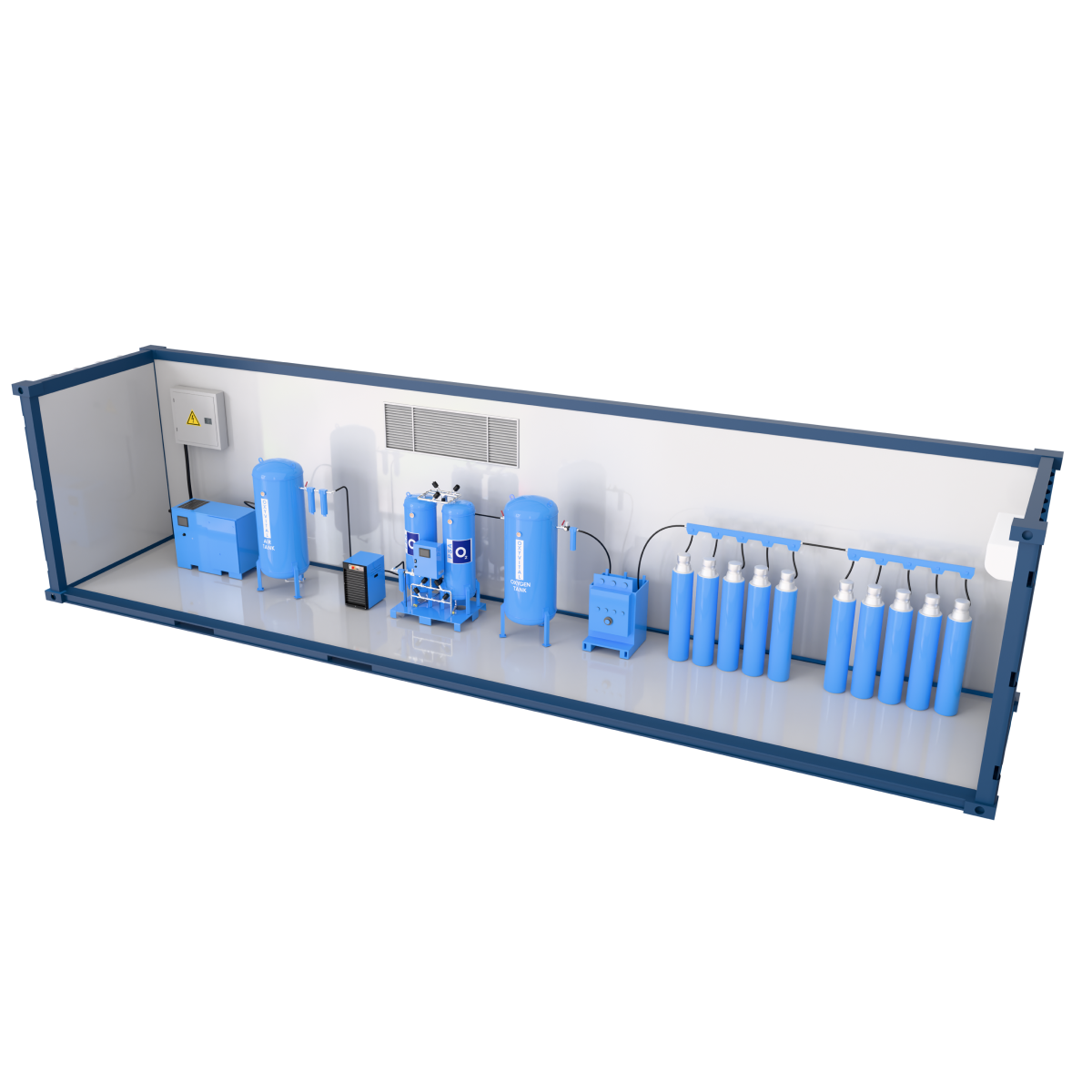

Oxygen Cylinder Filling Process with PSA Oxygen Generators

Oxyvital PSA generators enable you to produce oxygen while also setting up a cylinder filling station, ensuring a continuous and independent gas supply.

Key Features

PSA Oxygen Generation

The PSA generator produces oxygen with a purity of %96 and stores it in a buffer tank.

Use of a High-Pressure Oxygen Compressor

PSA systems generate oxygen at a pressure range of 4–10 bar, whereas cylinder filling requires 150–200 bar. Therefore, a high-pressure oxygen compressor is used to compress the oxygen to the required filling pressure.

Oxygen Cylinder Filling Manifold System

Multiple filling manifolds allow several cylinders to be filled simultaneously. Oxygen filling can be performed using manual or automated systems.

Safety Checks and Tests

Cylinders are inspected using pressure regulators and safety valves. Oxygen purity sensors ensure the gas meets the required quality before filling.

Cylinder Filling Systems

Step by Step Process

Cylinder Filling Systems

Advantages of Cylinder Filling

Produce your own oxygen, reduce dependency

* Eliminates cylinder ordering and logistics costs.

* Provides a continuous and reliable oxygen supply.

Low-cost and sustainable solution

* Saves 50-70% on liquid oxygen and cylinder filling costs.

* Energy-efficient system offers a long-term economical solution.

* Energy-efficient system offers a long-term economical solution.

Component

Function

PSA Oxygen Generator

Separates oxygen from air, producing oxygen at %96 purity

Buffer Tank (Storage Tank)

Stores oxygen from the PSA generator and provides a steady supply to the compressor

High-Pressure Oxygen Compressor

Compresses oxygen up to 150–200 bar for cylinder filling

Oxygen Cylinder Filling Manifold

Enables simultaneous filling of multiple cylinders

Filtration System

Removes particles and moisture from the oxygen

Pressure Sensors & Safety Valves

Ensure safety during the cylinder filling process

Cylinder Filling Systems

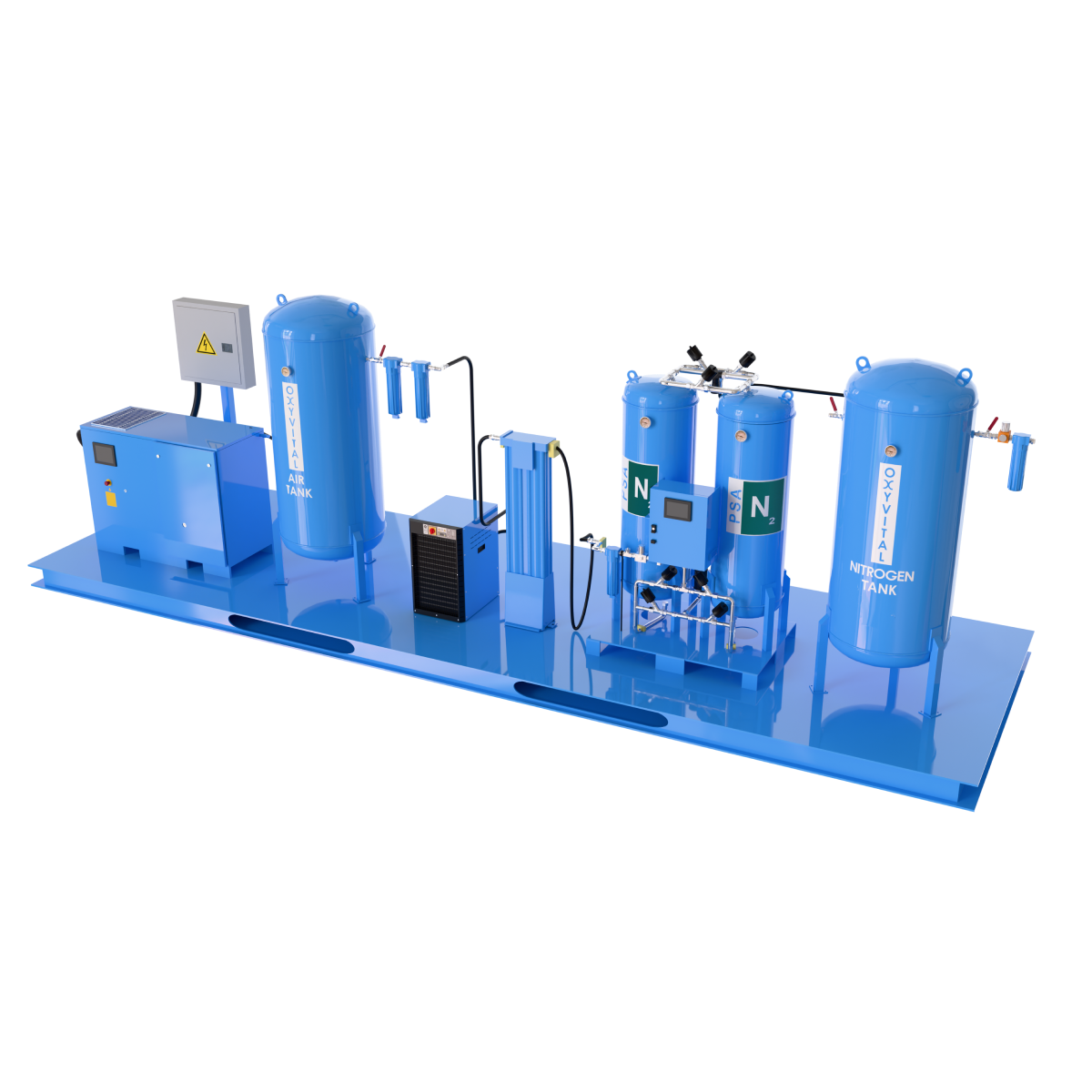

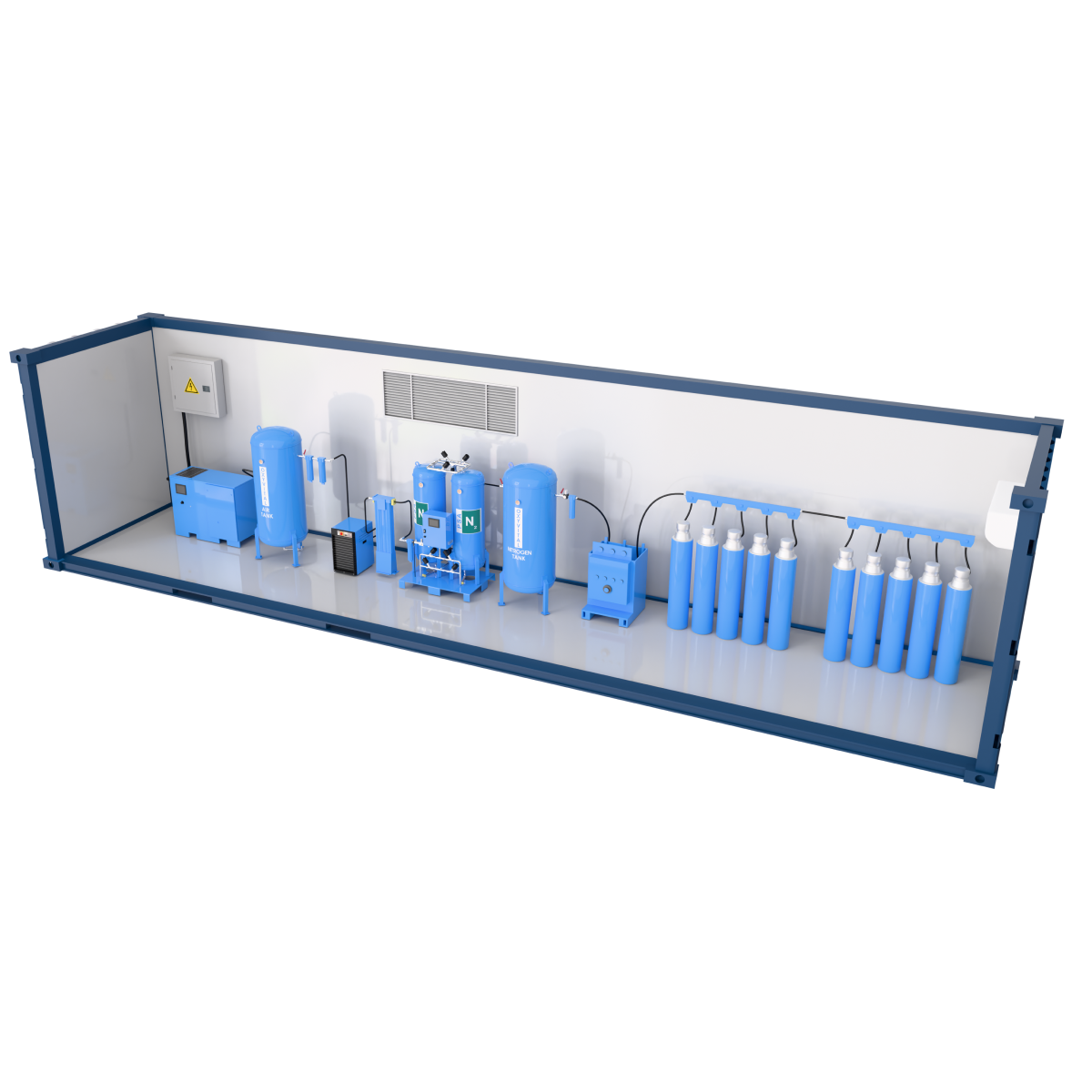

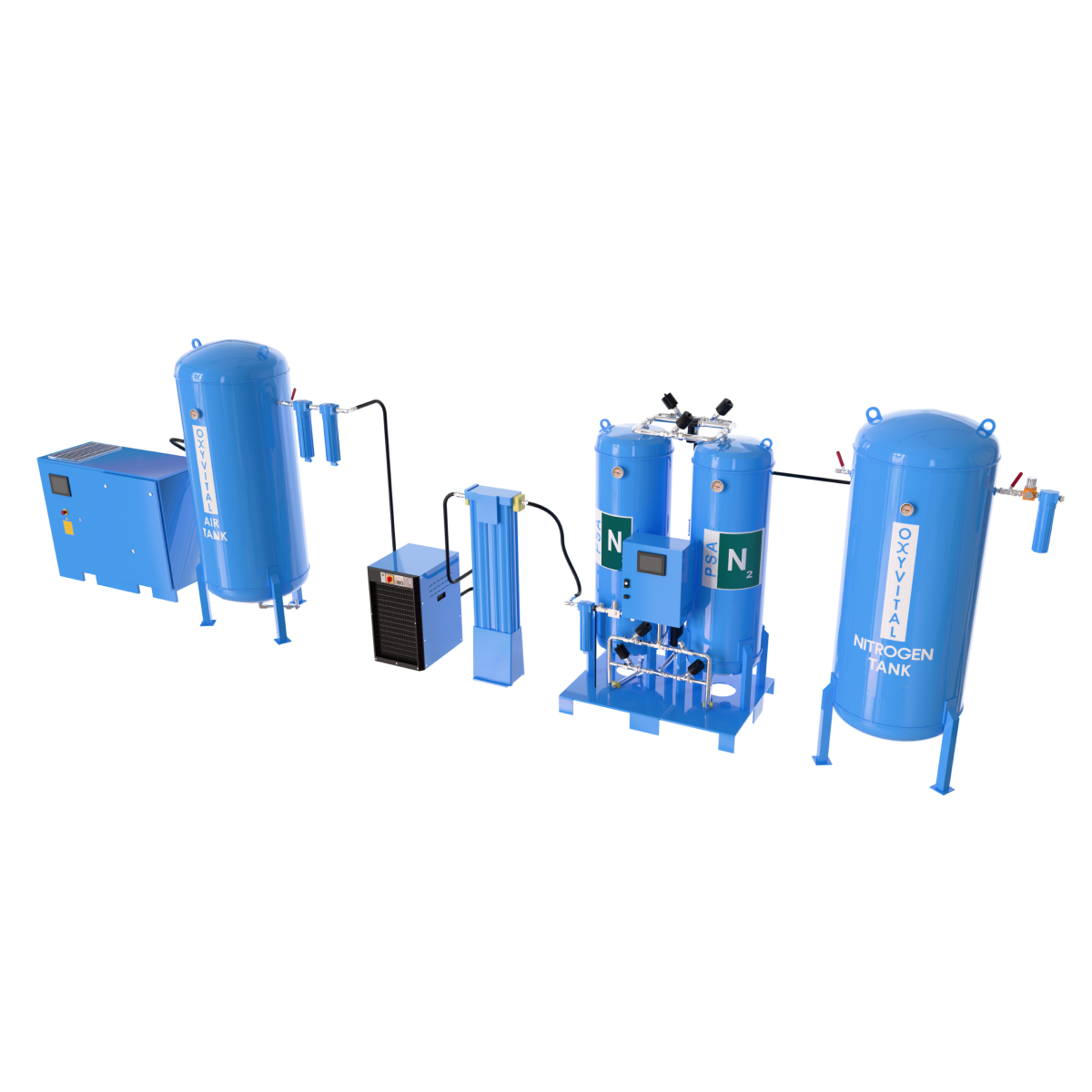

Nitrogen Gas Generators

Oxyvital PSA Nitrogen Generators are suitable not only for instant use but also for filling nitrogen cylinders; providing a continuous and economical supply of nitrogen for industries such as hospitals, laboratories, metal processing, food packaging, and oil and gas.

Nitrogen Cylinder Filling Process with PSA Nitrogen Generators

Nitrogen Production with PSA Generator

The PSA generator produces nitrogen with a purity of 95% to 99.999% and stores it in a buffer tank.

Use of High-Pressure Nitrogen Compressor

PSA generators produce nitrogen at a pressure range of 5–10 bar, but cylindrical cylinders typically require 150–300 bar. A high-pressure nitrogen compressor compresses the nitrogen to the required level for cylinder filling.

Nitrogen Cylinder Filling Manifold System

Multiple filling manifolds are used to fill more than one cylinder at a time. Automatic or manual filling systems enable safe filling of high-pressure nitrogen cylinders.

Safety Checks and Tests

Pressure regulators and safety valves ensure the process is carried out safely. Gas purity sensors check that the nitrogen meets the required quality before filling.