30+

Volume

B Series

5,85 – 24 Nm³/hour

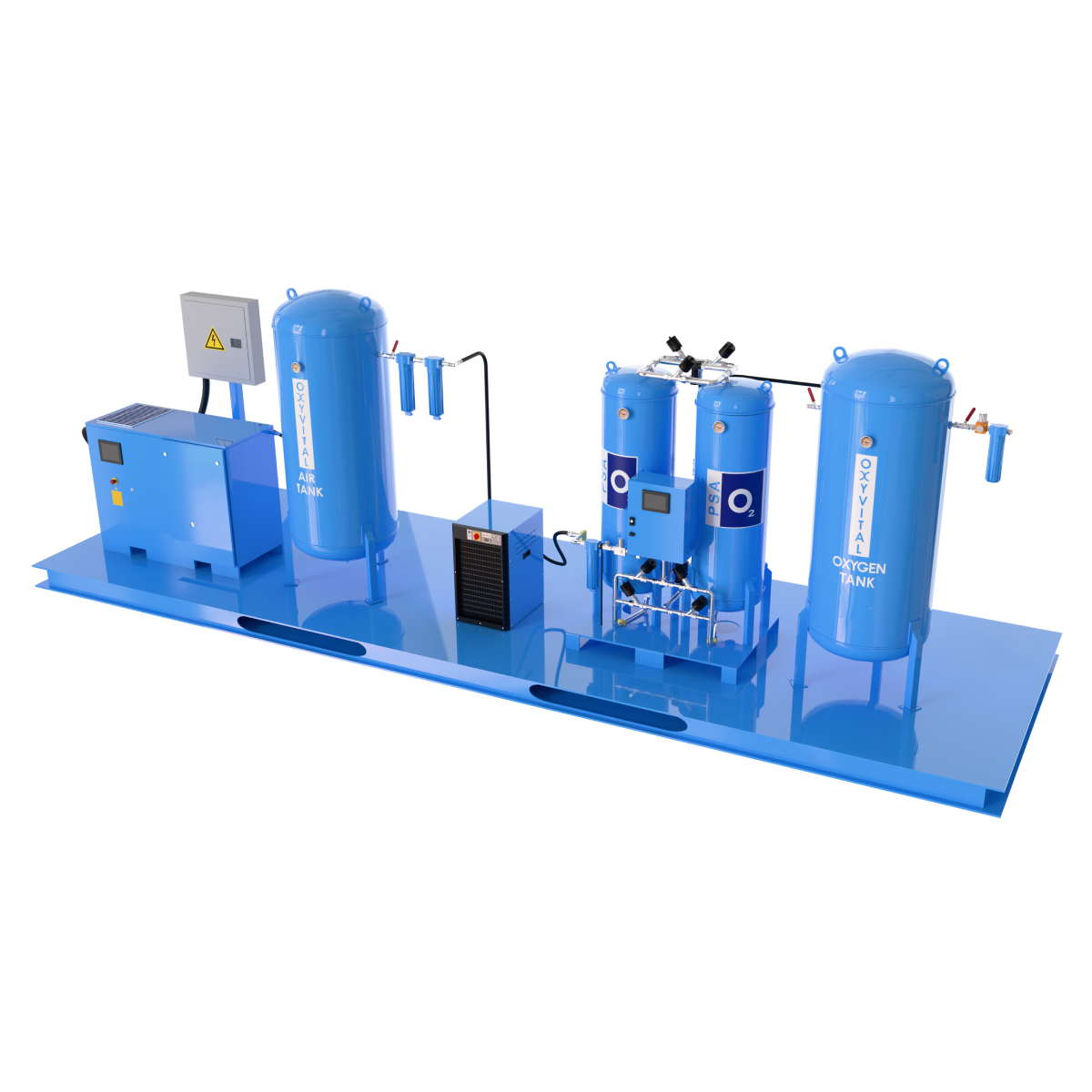

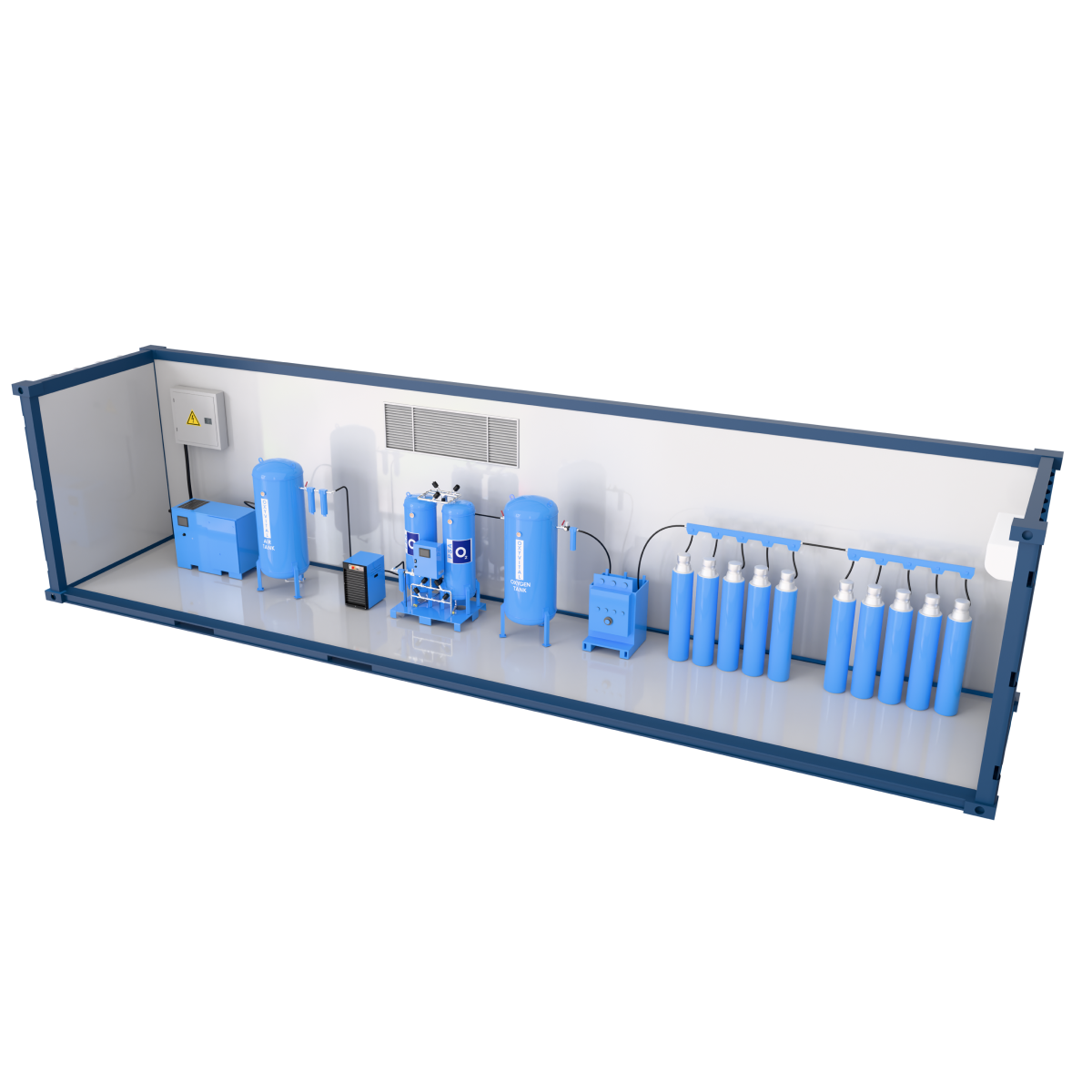

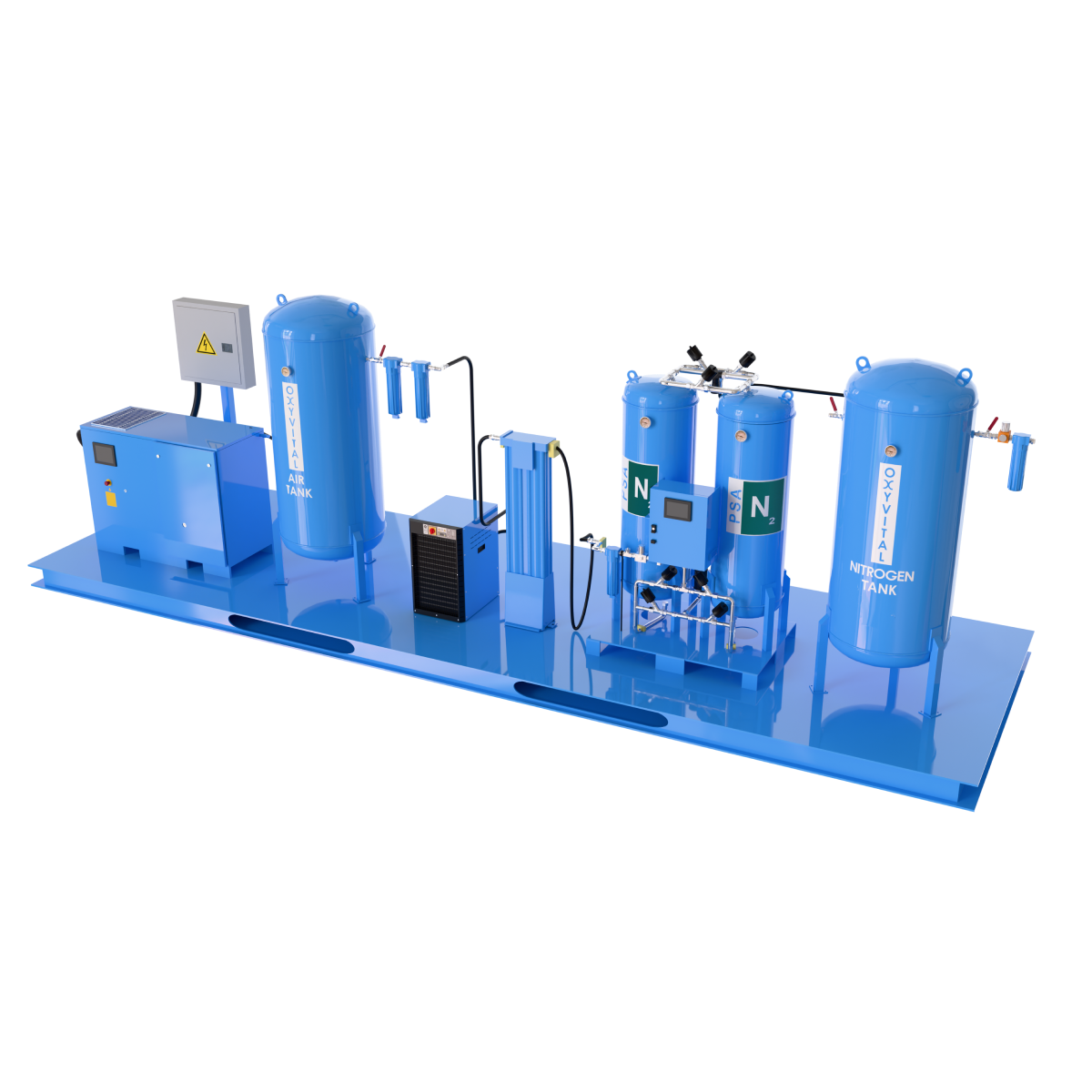

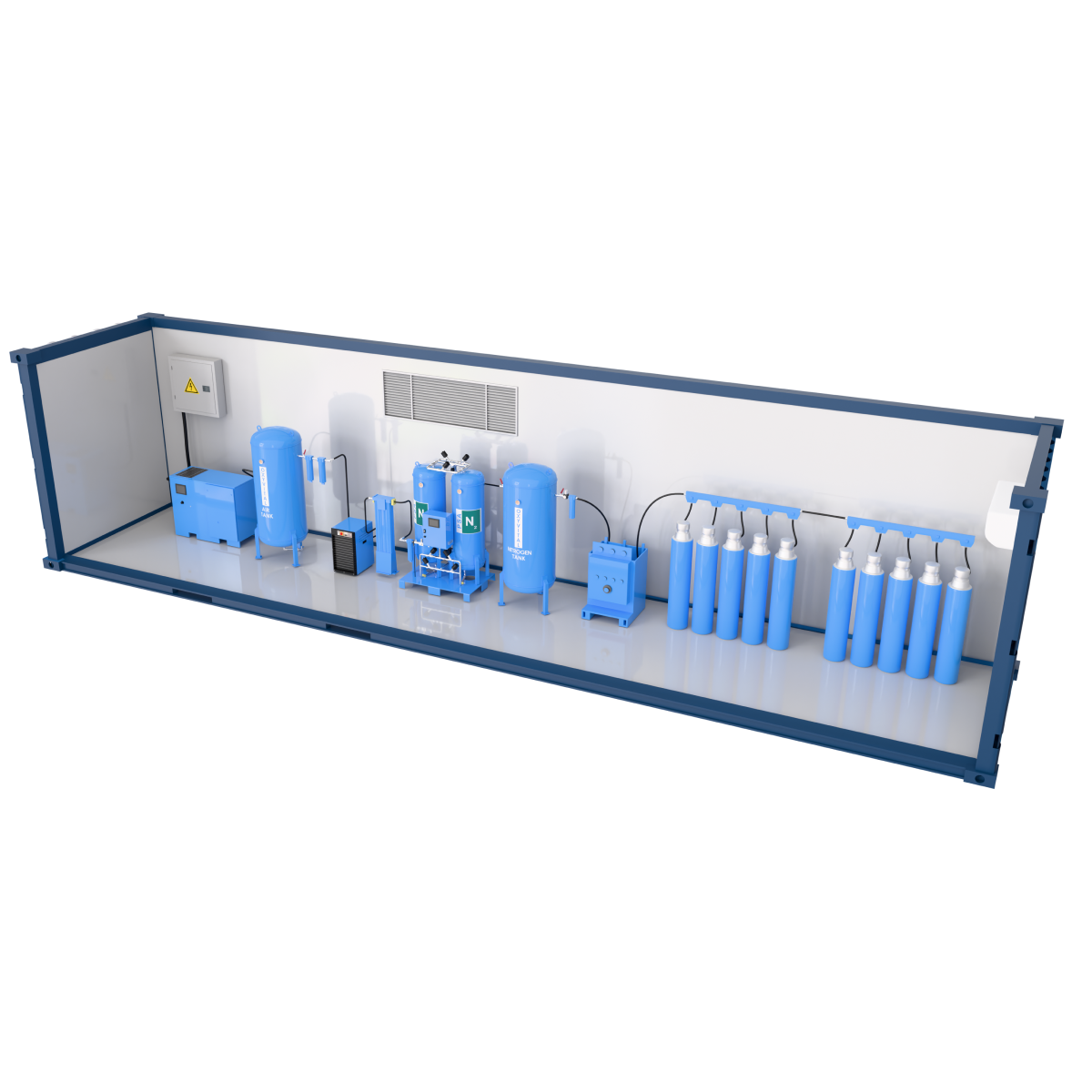

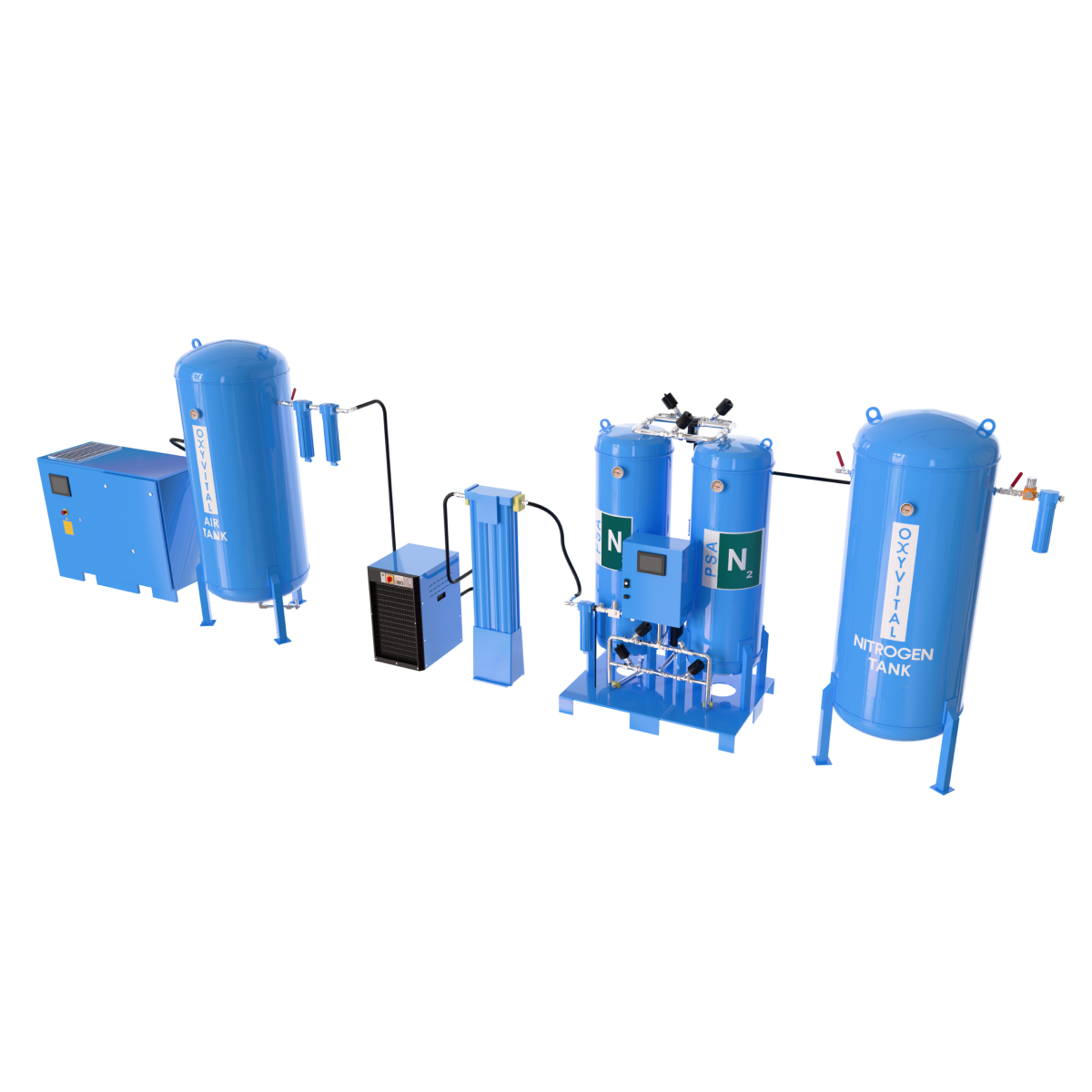

B Series – PSA Nitrogen Generators

High Purity, Small Scale

The OXYN B Series is designed to offer a compact structure, high efficiency, and flexible purity options in nitrogen production. Ideal for small and medium-sized businesses, this series can be reliably used in food packaging, laboratories, laser cutting, pharmaceutical production, and specialized industrial processes.

Applications

Food & Beverage

Prevents oxidation and extends shelf life in packaging lines.

Laboratory

Used in analytical instruments, gas chromatography, and inert atmosphere applications.

Industrial Production

Laser cutting, metal heat treatment, and plastic injection.

Pharmaceutical & Medical

Features That Distinguish the B Series from Other Series

Offers high purity options within a lower capacity range.

Specially designed for small businesses and laboratories.

Low initial investment cost.

Engineering focused on energy efficiency.

Portable installation capability (mobile frame options).

B Series – PSA Nitrogen Generators

Key Advantages of the B Series

B Series – PSA Nitrogen Generators

OXYN-05

Total Inert Gas Purity

%97

5,85

5,85

%99

5,18

5,18

%99,5

3,94

3,94

%99,9

2,83

2,83

%99,99

1,79

1,79

%99,999

0,93

0,93

Inlet Pressure (bar)

7,5

7,5

Nominal Capacity (Nm³/h)

5,85

5,85

Operating Temperature (°C)

30

30

Technology

PSA (Pressure Swing Adsorption) – Carbon Molecular Sieve (CMS)

PSA (Pressure Swing Adsorption) – Carbon Molecular Sieve (CMS)

Power Source

Compressed air (supplied by compressor)

Compressed air (supplied by compressor)

Control System

PLC-based automation, touch screen

PLC-based automation, touch screen

Model Range

OXYN-05, OXYN-10, OXYN-15, OXYN-25

OXYN-05, OXYN-10, OXYN-15, OXYN-25

OXYN-1O

Total Inert Gas Purity

%97

9,50

9,50

%99

8,55

8,55

%99,5

6,05

6,05

%99,9

4,86

4,86

%99,99

3,17

3,17

%99,999

2,04

2,04

Inlet Pressure (bar)

7,5

7,5

Nominal Capacity (Nm³/h)

5,85

5,85

Operating Temperature (°C)

30

30

Technology

PSA (Pressure Swing Adsorption) – Carbon Molecular Sieve (CMS)

PSA (Pressure Swing Adsorption) – Carbon Molecular Sieve (CMS)

Power Source

Compressed air (supplied by compressor)

Compressed air (supplied by compressor)

Control System

PLC-based automation, touch screen

PLC-based automation, touch screen

Model Range

OXYN-05, OXYN-10, OXYN-15, OXYN-25

OXYN-05, OXYN-10, OXYN-15, OXYN-25

OXYN-15

Total Inert Gas Purity

%97

15,0

15,0

%99

13,2

13,2

%99,5

9,5

9,5

%99,9

7,4

7,4

%99,99

4,6

4,6

%99,999

2,8

2,8

Inlet Pressure (bar)

7,5

7,5

Nominal Capacity (Nm³/h)

5,85

5,85

Operating Temperature (°C)

30

30

Technology

PSA (Pressure Swing Adsorption) – Carbon Molecular Sieve (CMS)

PSA (Pressure Swing Adsorption) – Carbon Molecular Sieve (CMS)

Power Source

Compressed air (supplied by compressor)

Compressed air (supplied by compressor)

Control System

PLC-based automation, touch screen

PLC-based automation, touch screen

Model Range

OXYN-05, OXYN-10, OXYN-15, OXYN-25

OXYN-05, OXYN-10, OXYN-15, OXYN-25

OXYN-25

Total Inert Gas Purity

%97

24,0

24,0

%99

21,1

21,1

%99,5

15,2

15,2

%99,9

11,4

11,4

%99,99

6,8

6,8

%99,999

3,9

3,9

Inlet Pressure (bar)

7,5

7,5

Nominal Capacity (Nm³/h)

5,85

5,85

Operating Temperature (°C)

30

30

Technology

PSA (Pressure Swing Adsorption) – Carbon Molecular Sieve (CMS)

PSA (Pressure Swing Adsorption) – Carbon Molecular Sieve (CMS)

Power Source

Compressed air (supplied by compressor)

Compressed air (supplied by compressor)

Control System

PLC-based automation, touch screen

PLC-based automation, touch screen

Model Range

OXYN-05, OXYN-10, OXYN-15, OXYN-25

OXYN-05, OXYN-10, OXYN-15, OXYN-25

Required Compressed Air Calculation

N2 Purity

97

99

99,5

99,9

99,99

99,999

Air Factor

2,1

2,5

2,9

3,9

5,5

8-10

Use of Oxygen Sensors According to Purity Percentages

N2 Purity

97,00%

99,00%

99,50%

99,90%

99,99%

99,999%

Zirconia Sensors

-

-

-

True

True

True

Electrochemical Sensors

True

True

True

-

-

-