30+

Volume

J Series

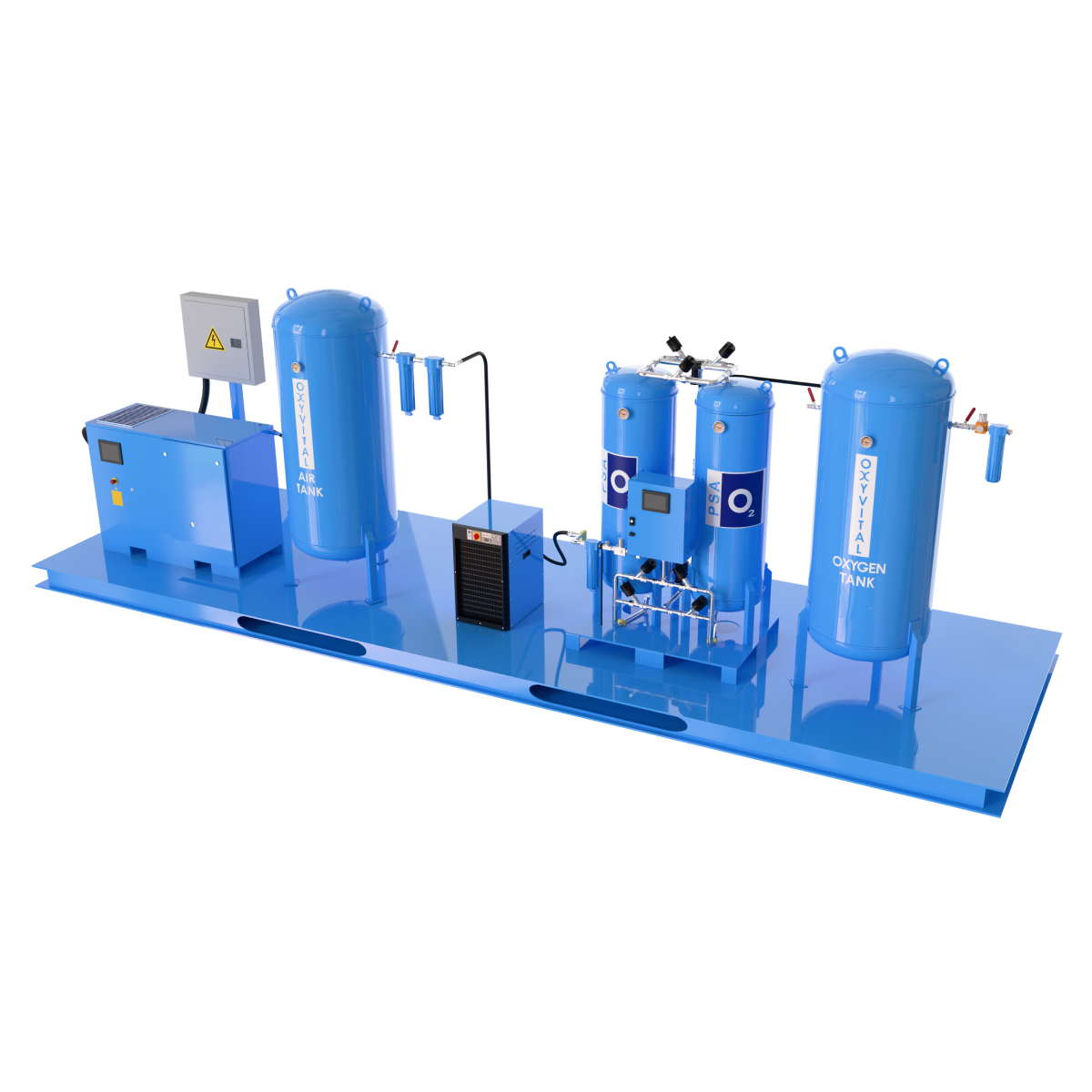

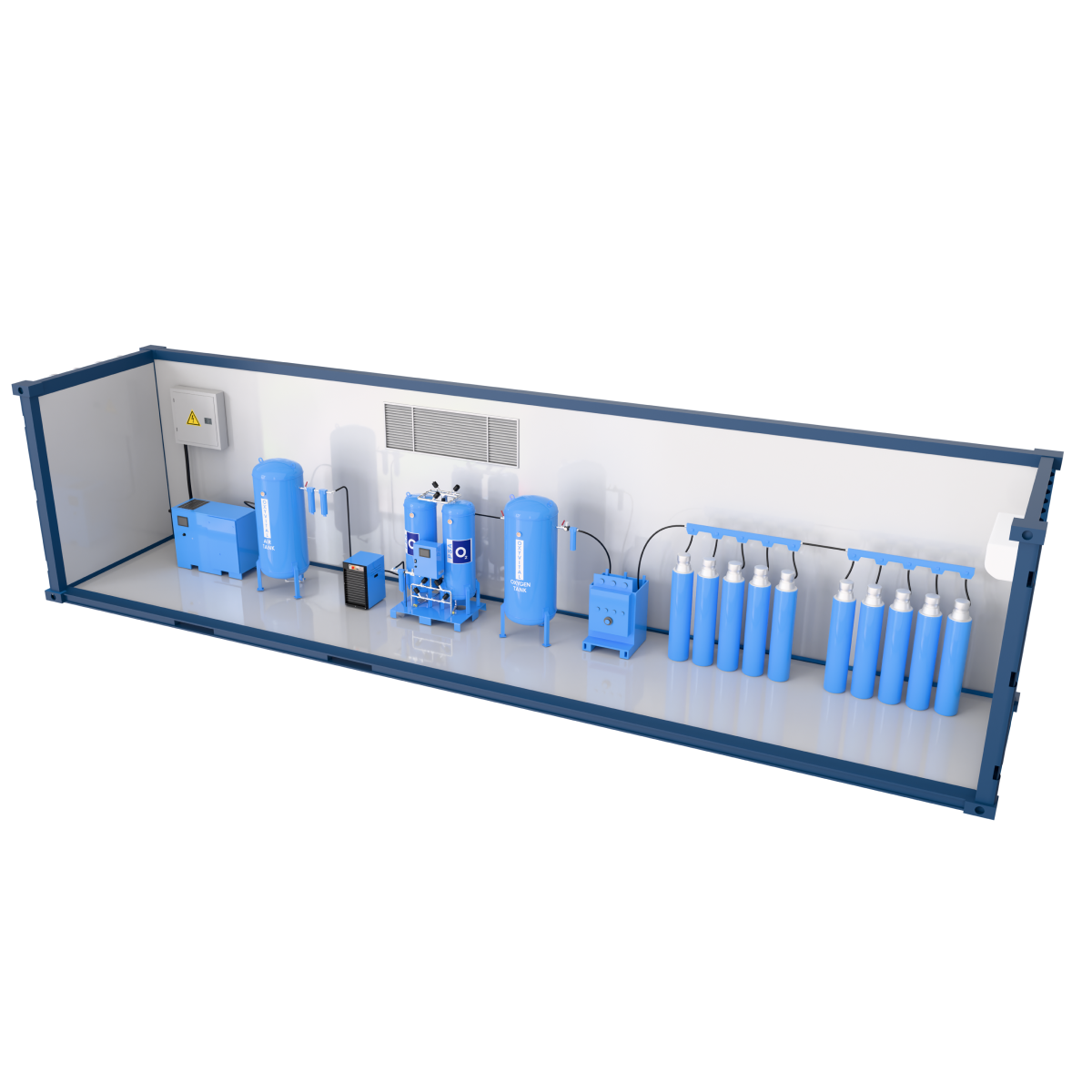

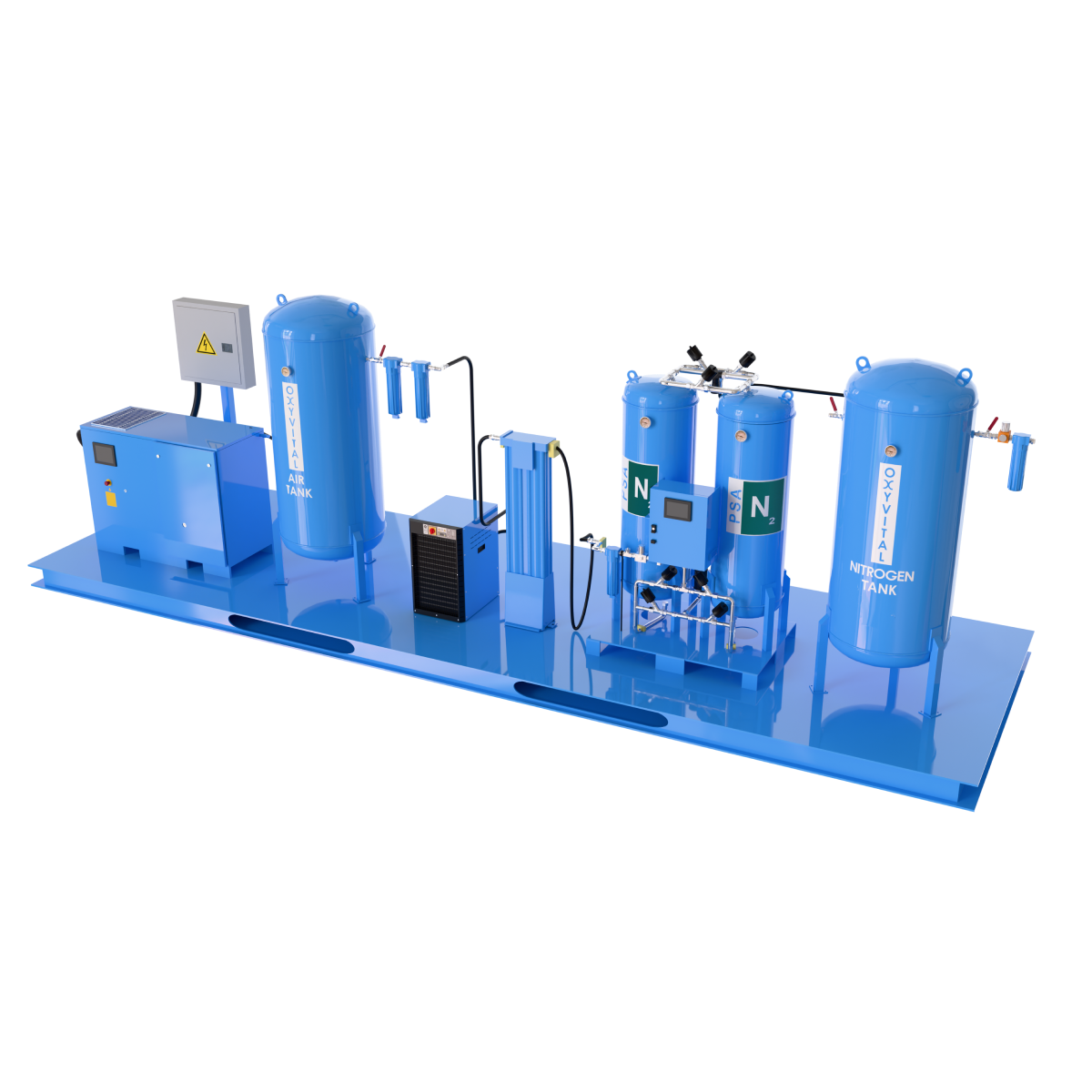

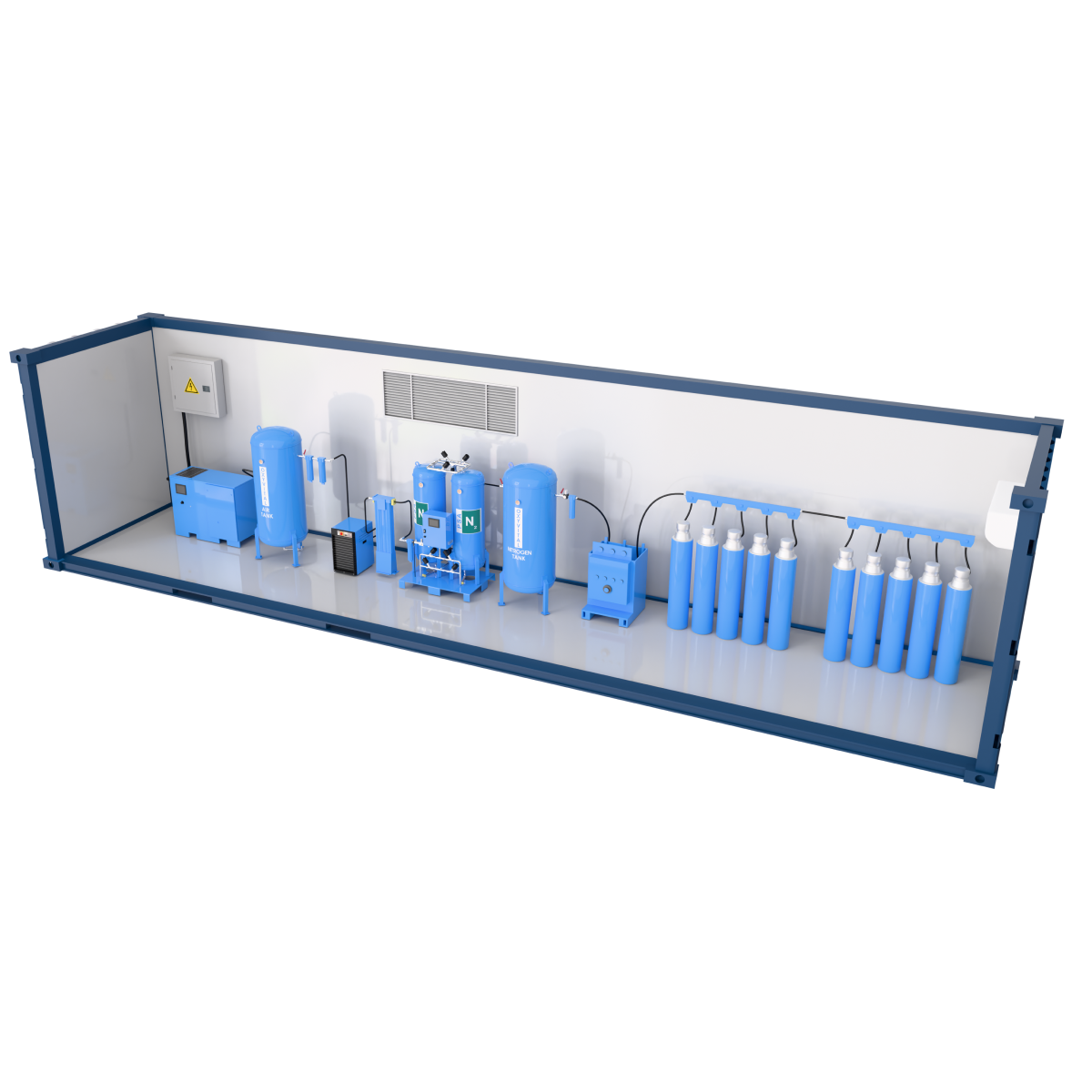

28.7 -87 Nm³/hour

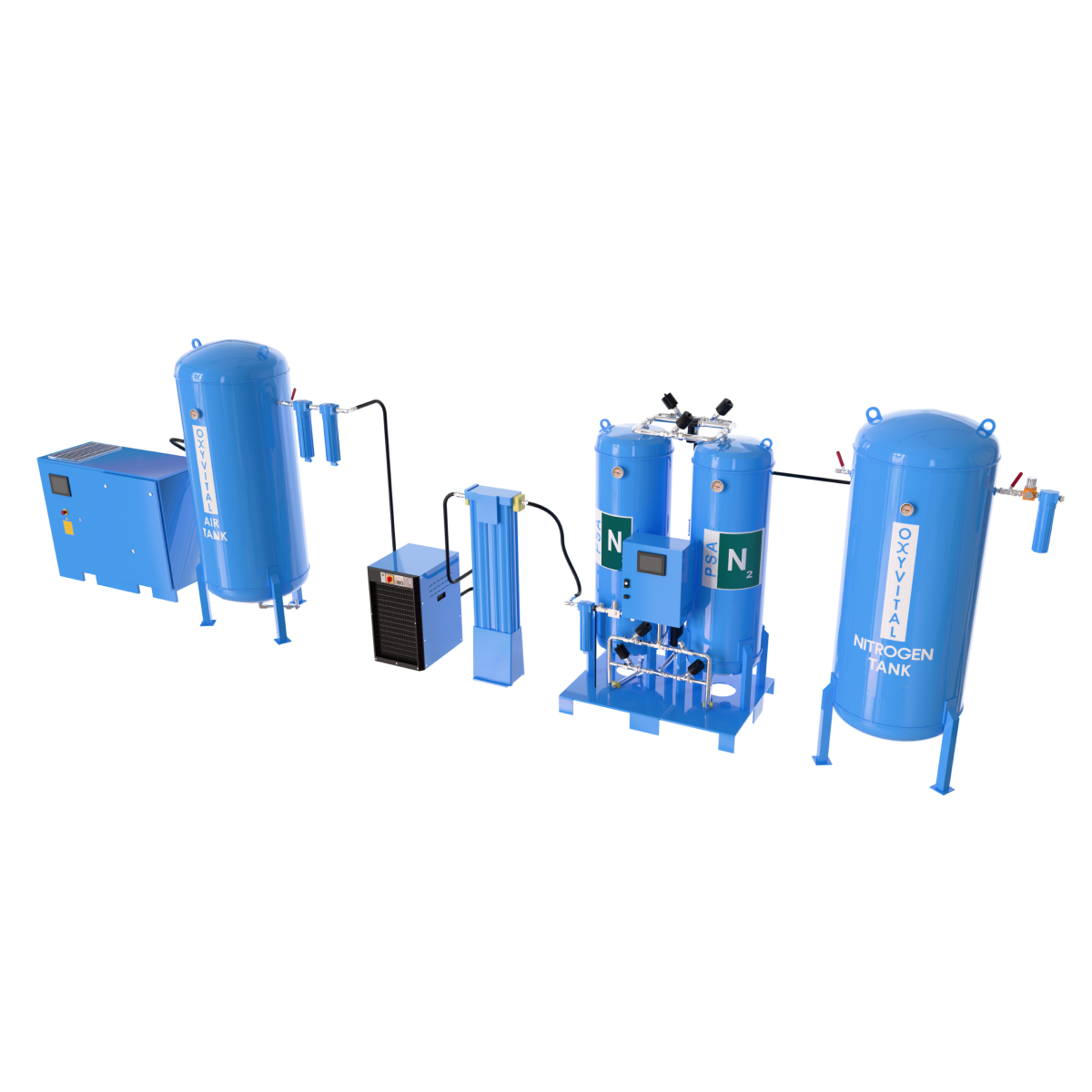

J Series - PSA Nitrogen Generators

Medium Capacity, High Performance

OXYN J Series are high-efficiency PSA nitrogen generators designed for medium-sized enterprises and high-volume production lines. With industrial-grade durability, a wide range of capacity options, and purity levels of up to 99.999%, they are especially preferred in the food, pharmaceutical, laser cutting, and process industries.

Applications

Food Industry

Packaging, MAP (Modified Atmosphere Packaging) systems.

Metal Processing

Laser cutting, heat treatment processes.

Chemical and Petrochemical

Removal of oxygen from reactive environments.

Pharmaceutical and Medical

Pharmaceutical production, ensuring a sterile environment.

Features Distinguishing the J Series from the B Series

Higher capacity range (28.7 – 87 Nm³/h).

Special design for medium and large-scale industrial facilities.

Higher air efficiency and enhanced automation options.

J Series - PSA Nitrogen Generators

Key Advantages of the J Series

J Series – PSA Nitrogen Generators

OXYN-30

Total Inert Gas Purity

%97

28,7

28,7

%99

25,2

25,2

%99,5

17,8

17,8

%99,9

13,5

13,5

%99,99

8,0

8,0

%99,999

4,5

4,5

Inlet Pressure (bar)

7,5

7,5

Nominal Capacity (Nm³/h)

28,7

28,7

Operating Temperature (°C)

30

30

Technology

PSA (Pressure Swing Adsorption) – Carbon Molecular Sieve (CMS)

PSA (Pressure Swing Adsorption) – Carbon Molecular Sieve (CMS)

Control System

PLC-based automation, touchscreen control

PLC-based automation, touchscreen control

Model Range

OXYN-30, OXYN-45, OXYN-70, OXYN-90

OXYN-30, OXYN-45, OXYN-70, OXYN-90

OXYN-45

Total Inert Gas Purity

%97

43,0

43,0

%99

37,8

37,8

%99,5

26,8

26,8

%99,9

20,3

20,3

%99,99

12,1

12,1

%99,999

6,9

6,9

Inlet Pressure (bar)

7,5

7,5

Nominal Capacity (Nm³/h)

43,0

43,0

Operating Temperature (°C)

30

30

Technology

PSA (Pressure Swing Adsorption) – Carbon Molecular Sieve (CMS)

PSA (Pressure Swing Adsorption) – Carbon Molecular Sieve (CMS)

Control System

PLC-based automation, touchscreen control

PLC-based automation, touchscreen control

Model Range

OXYN-30, OXYN-45, OXYN-70, OXYN-90

OXYN-30, OXYN-45, OXYN-70, OXYN-90

OXYN-70

Total Inert Gas Purity

%97

67,5

67,5

%99

59,3

59,3

%99,5

41,8

41,8

%99,9

31,6

31,6

%99,99

18,5

18,5

%99,999

10,3

10,3

Inlet Pressure (bar)

7,5

7,5

Nominal Capacity (Nm³/h)

67,5

67,5

Operating Temperature (°C)

30

30

Technology

PSA (Pressure Swing Adsorption) – Carbon Molecular Sieve (CMS)

PSA (Pressure Swing Adsorption) – Carbon Molecular Sieve (CMS)

Control System

PLC-based automation, touchscreen control

PLC-based automation, touchscreen control

Model Range

OXYN-30, OXYN-45, OXYN-70, OXYN-90

OXYN-30, OXYN-45, OXYN-70, OXYN-90

OXYN-90

Total Inert Gas Purity

%97

87,0

87,0

%99

76,4

76,4

%99,5

54,1

54,1

%99,9

40,9

40,9

%99,99

24,1

24,1

%99,999

13,5

13,5

Inlet Pressure (bar)

7,5

7,5

Nominal Capacity (Nm³/h)

87,0

87,0

Operating Temperature (°C)

30

30

Technology

PSA (Pressure Swing Adsorption) – Carbon Molecular Sieve (CMS)

PSA (Pressure Swing Adsorption) – Carbon Molecular Sieve (CMS)

Control System

PLC-based automation, touchscreen control

PLC-based automation, touchscreen control

Model Range

OXYN-30, OXYN-45, OXYN-70, OXYN-90

OXYN-30, OXYN-45, OXYN-70, OXYN-90

Required Compressed Air Calculation

N2 Purity

97

99

99,5

99,9

99,99

99,999

Air Factor

2,1

2,5

2,9

3,9

5,5

8-10

Use of Oxygen Sensors According to Purity Percentages

N2 Purity

97,00%

99,00%

99,50%

99,90%

99,99%

99,999%

Zirconia Sensors

-

-

-

True

True

True

Electrochemical Sensors

True

True

True

-

-

-