30+

Volume

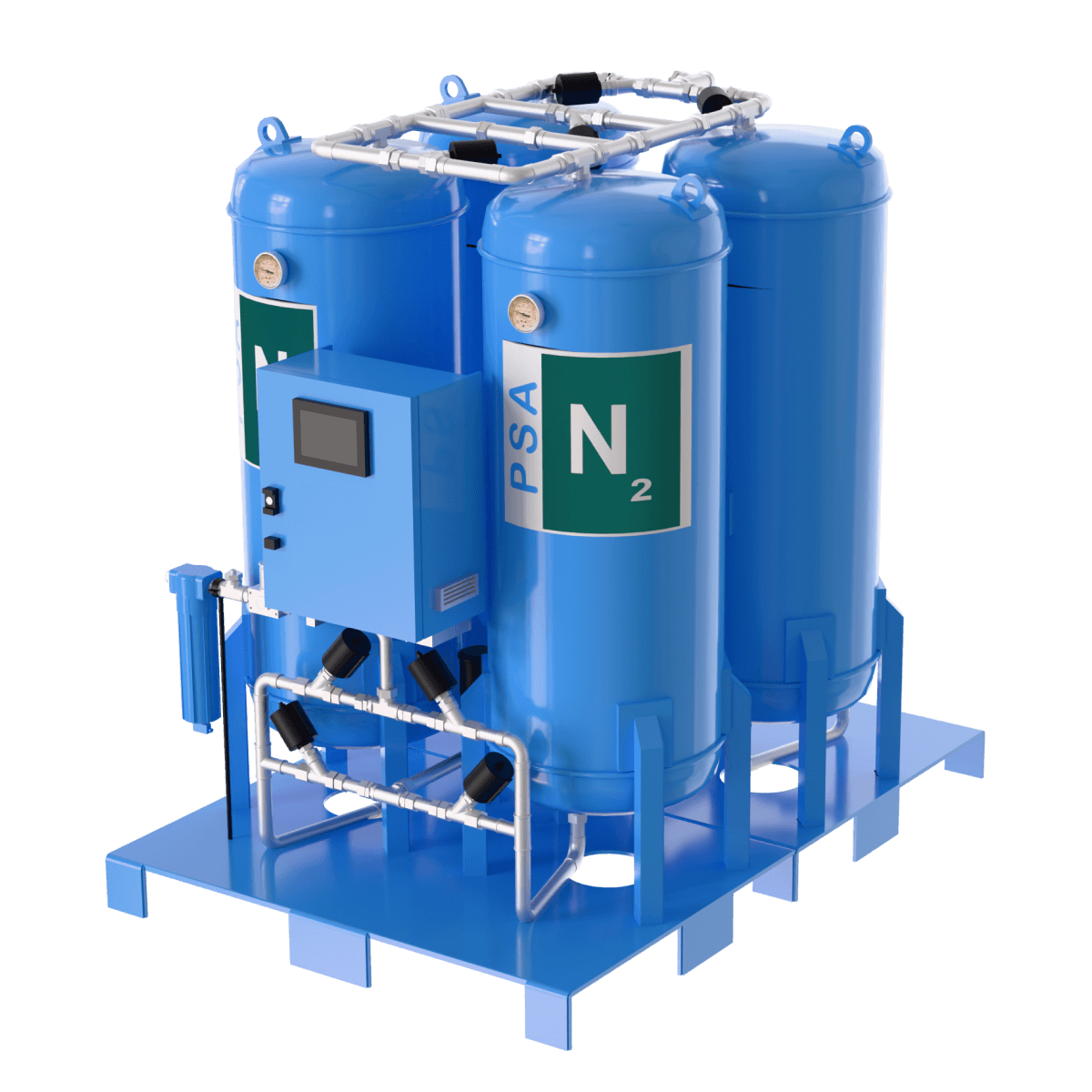

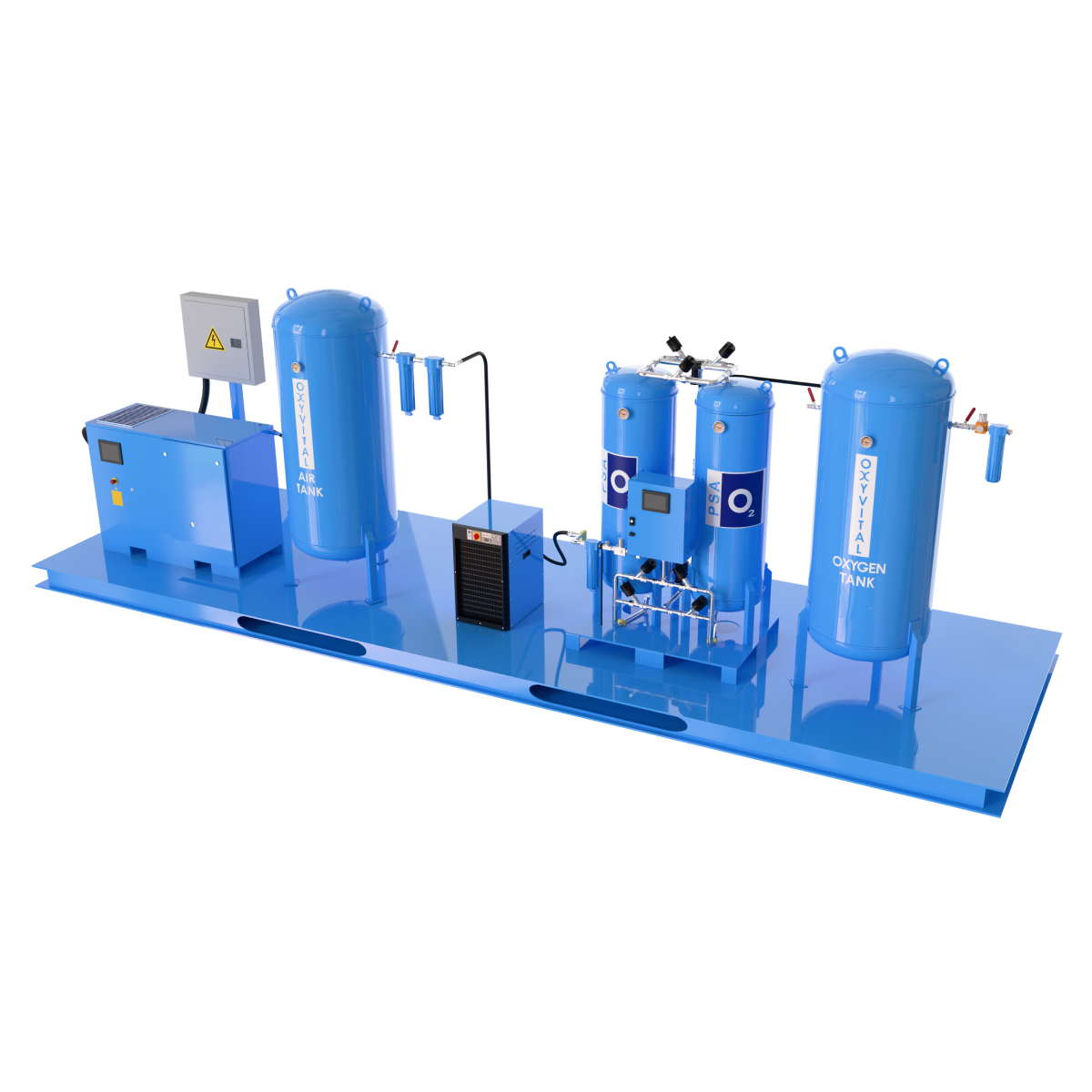

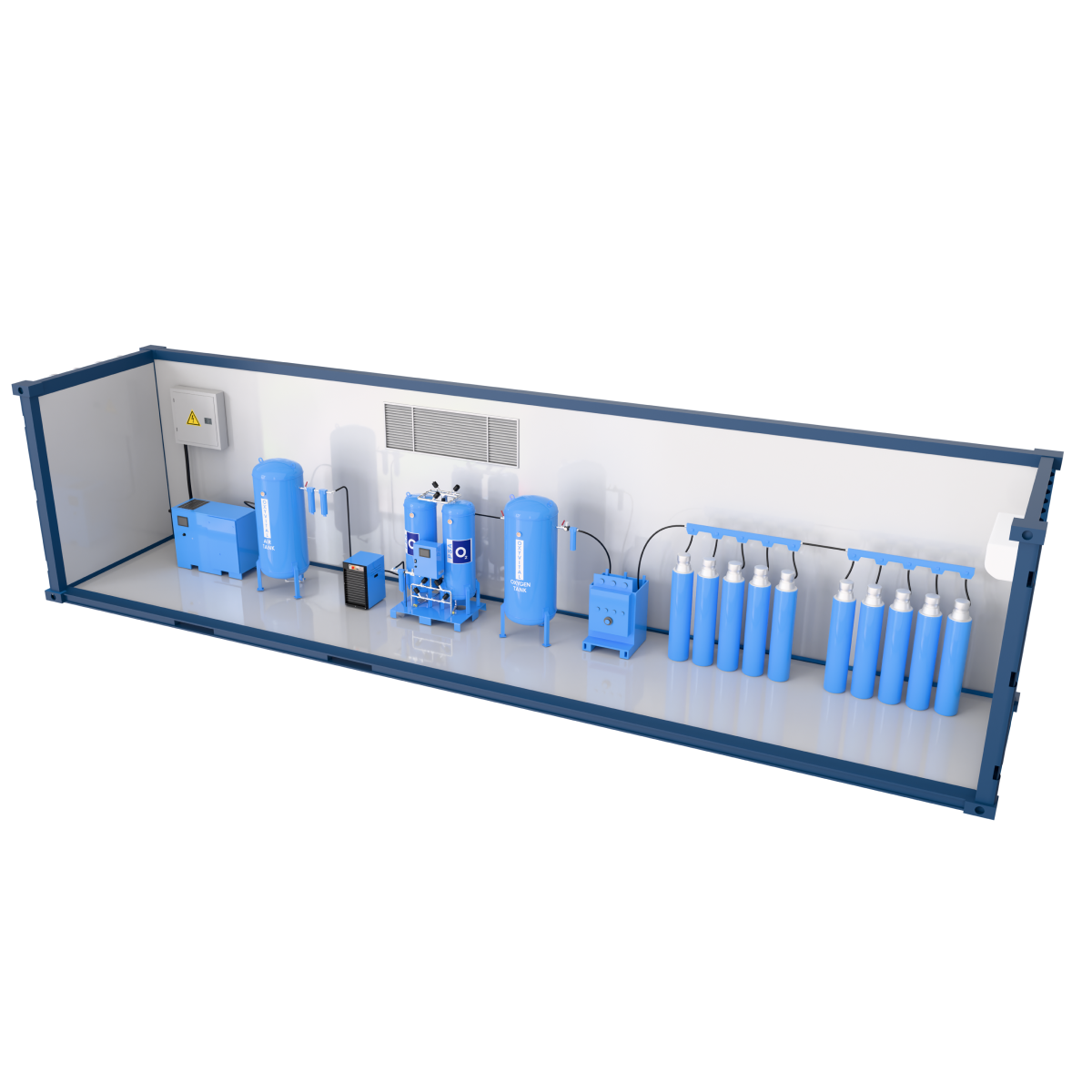

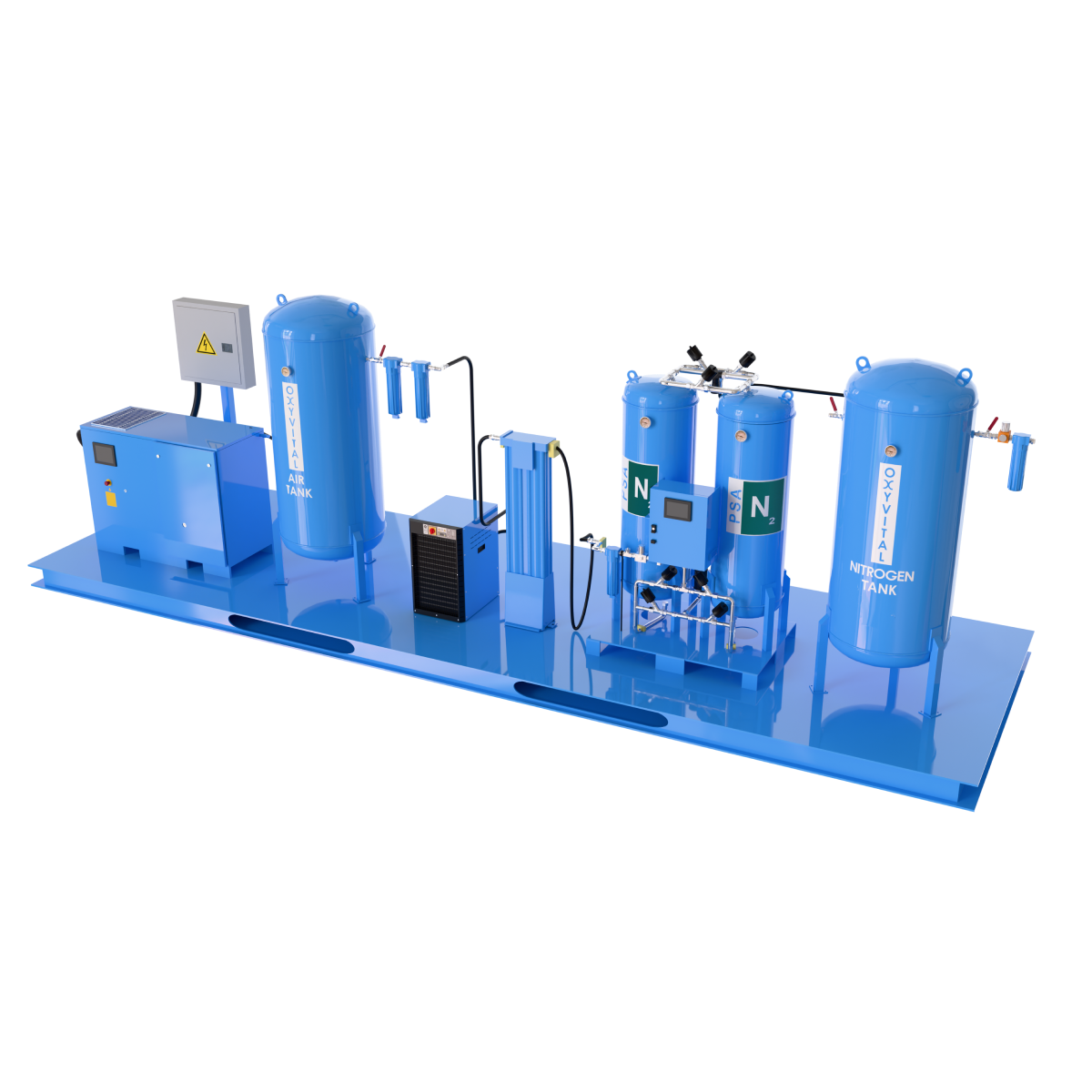

K Series

107 – 274 Nm³/hour

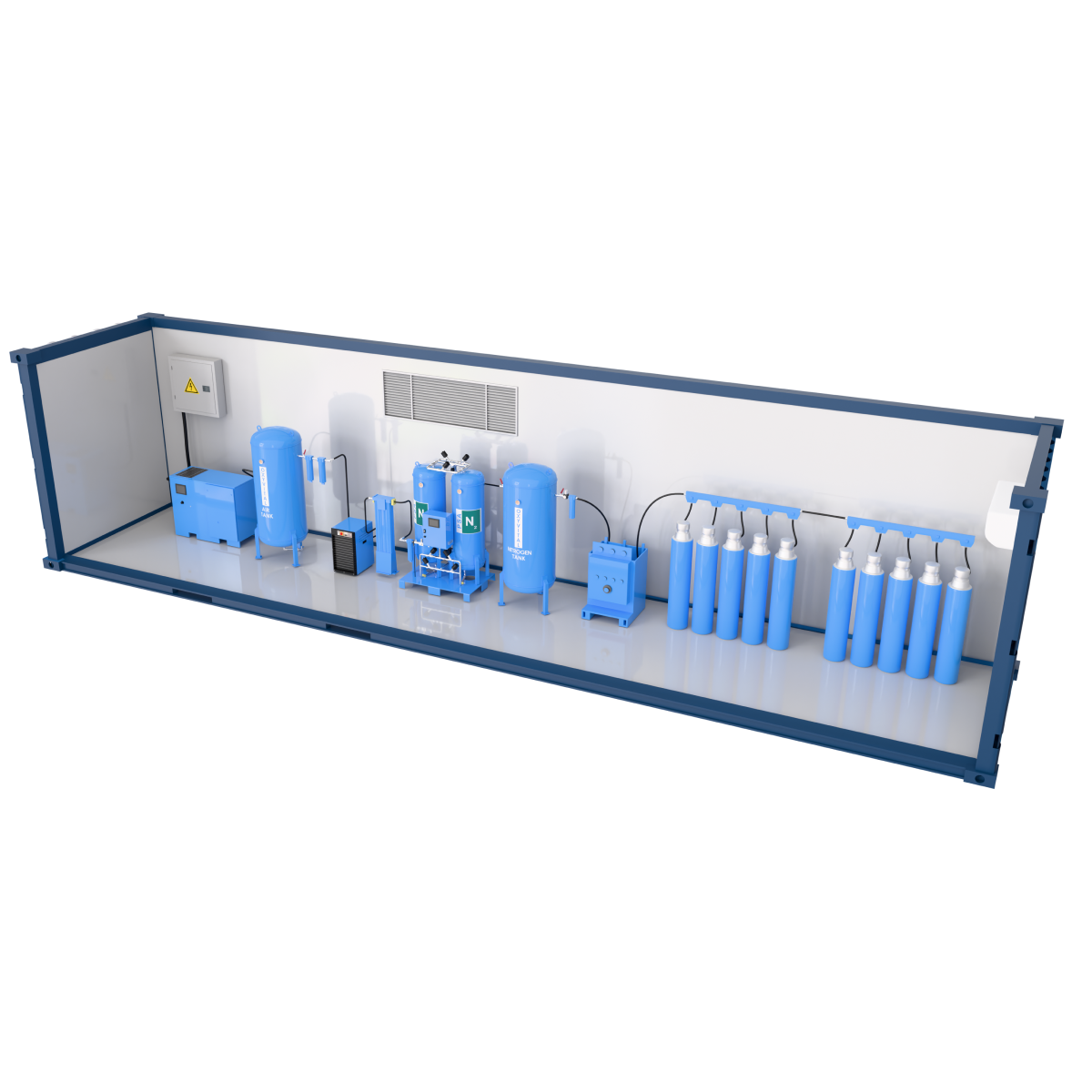

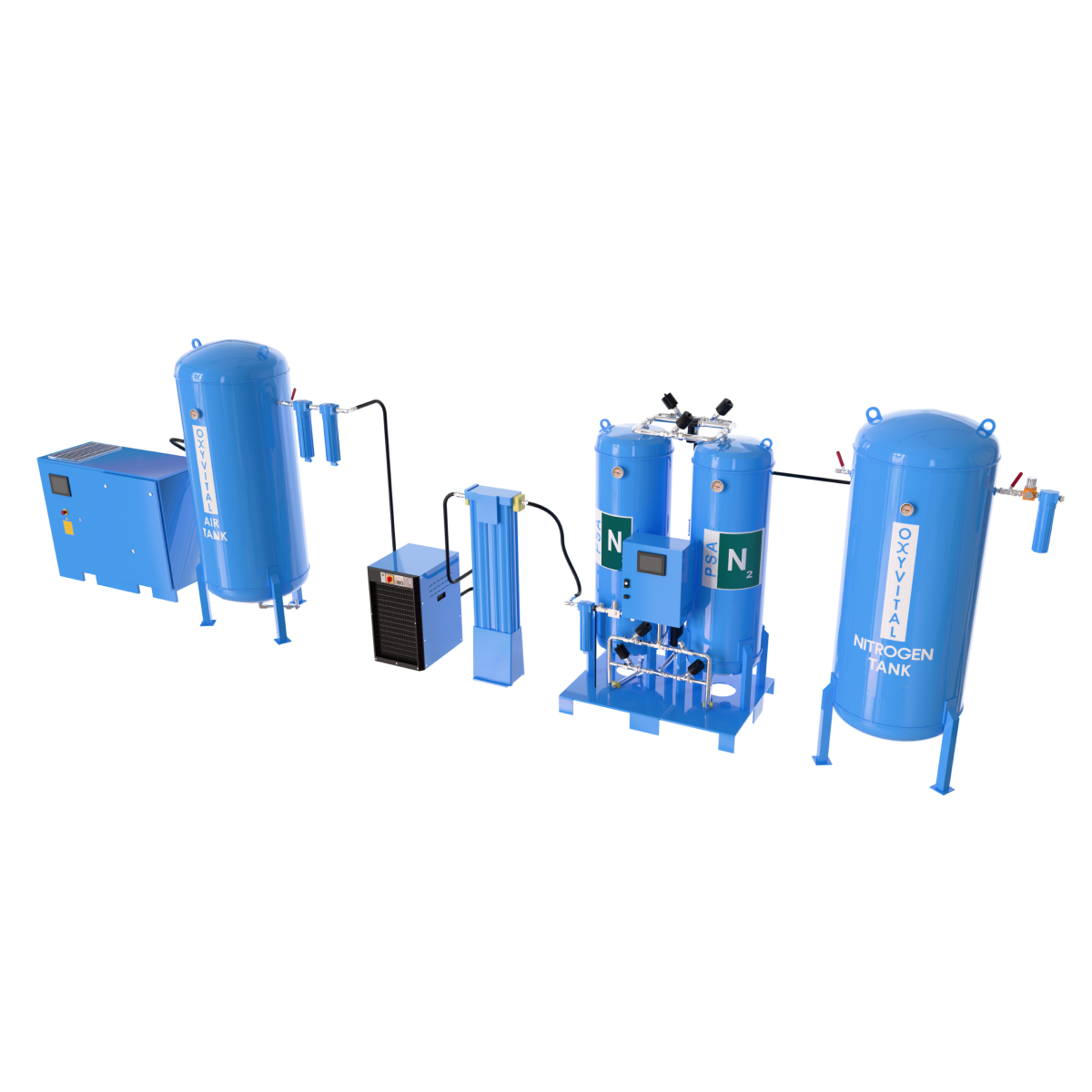

K Series - PSA Nitrogen Generators

High Capacity, The Address of Industrial Power

OXYN K Series are industrial-grade PSA generators designed to meet high-volume nitrogen demands. With purity levels of up to 99.999% and capacity options exceeding 100 Nm³/h, they are preferred in large manufacturing plants, heavy industry, petrochemical, and food sectors.

Engineered for 24/7 uninterrupted production, the K Series offers maximum reliability through durable components, advanced automation, and minimal maintenance requirements.

Applications

Petrochemical and Refineries

Safe supply of inert gas in explosive environments.

Metal Processing

Laser cutting, heat treatment, powder metallurgy.

Food Industry

Large-scale packaging and storage processes.

Chemical Industry

Reaction control, solvent recovery systems.

Features Distinguishing the K Series from the J Series

Significantly higher capacity (107 – 274 Nm³/h).

Designed for large-scale industrial production and facilities requiring continuous operation.

Reinforced steel body and high-capacity valve assemblies.

K Series - PSA Nitrogen Generators

Key Advantages of the K Series

K Series – PSA Nitrogen Generators

OXYN-110

Total Inert Gas Purity

%97

107,0

107,0

%99

94,0

94,0

%99,5

66,6

66,6

%99,9

50,5

50,5

%99,99

29,8

29,8

%99,999

16,9

16,9

Inlet Pressure (bar)

7,5

7,5

Nominal Capacity (Nm³/h)

107,0

107,0

Operating Temperature (°C)

30

30

Technology

PSA (Pressure Swing Adsorption) – Carbon Molecular Sieve (CMS)

PSA (Pressure Swing Adsorption) – Carbon Molecular Sieve (CMS)

Operating Mode

Fully automatic, unmanned operation

Fully automatic, unmanned operation

Control System

PLC automation, touchscreen control

PLC automation, touchscreen control

Power Source

OXYN-110, OXYN-120, OXYN-180, OXYN-280

OXYN-110, OXYN-120, OXYN-180, OXYN-280

OXYN-120

Total Inert Gas Purity

%97

119,8

119,8

%99

105,4

105,4

%99,5

74,8

74,8

%99,9

56,8

56,8

%99,99

33,8

33,8

%99,999

19,4

19,4

Inlet Pressure (bar)

7,5

7,5

Nominal Capacity (Nm³/h)

119,8

119,8

Operating Temperature (°C)

30

30

Technology

PSA (Pressure Swing Adsorption) – Carbon Molecular Sieve (CMS)

PSA (Pressure Swing Adsorption) – Carbon Molecular Sieve (CMS)

Operating Mode

Fully automatic, unmanned operation

Fully automatic, unmanned operation

Control System

PLC automation, touchscreen control

PLC automation, touchscreen control

Power Source

OXYN-110, OXYN-120, OXYN-180, OXYN-280

OXYN-110, OXYN-120, OXYN-180, OXYN-280

OXYN-180

Total Inert Gas Purity

%97

179,0

179,0

%99

156,8

156,8

%99,5

110,9

110,9

%99,9

83,9

83,9

%99,99

49,4

49,4

%99,999

27,7

27,7

Inlet Pressure (bar)

7,5

7,5

Nominal Capacity (Nm³/h)

179,0

179,0

Operating Temperature (°C)

30

30

Technology

PSA (Pressure Swing Adsorption) – Carbon Molecular Sieve (CMS)

PSA (Pressure Swing Adsorption) – Carbon Molecular Sieve (CMS)

Operating Mode

Fully automatic, unmanned operation

Fully automatic, unmanned operation

Control System

PLC automation, touchscreen control

PLC automation, touchscreen control

Power Source

OXYN-110, OXYN-120, OXYN-180, OXYN-280

OXYN-110, OXYN-120, OXYN-180, OXYN-280

OXYN-280

Total Inert Gas Purity

%97

274,0

274,0

%99

240,8

240,8

%99,5

170,2

170,2

%99,9

128,7

128,7

%99,99

75,6

75,6

%99,999

42,4

42,4

Inlet Pressure (bar)

7,5

7,5

Nominal Capacity (Nm³/h)

274,0

274,0

Operating Temperature (°C)

30

30

Technology

PSA (Pressure Swing Adsorption) – Carbon Molecular Sieve (CMS)

PSA (Pressure Swing Adsorption) – Carbon Molecular Sieve (CMS)

Operating Mode

Fully automatic, unmanned operation

Fully automatic, unmanned operation

Control System

PLC automation, touchscreen control

PLC automation, touchscreen control

Power Source

OXYN-110, OXYN-120, OXYN-180, OXYN-280

OXYN-110, OXYN-120, OXYN-180, OXYN-280

Required Compressed Air Calculation

N2 Purity

97

99

99,5

99,9

99,99

99,999

Air Factor

2,1

2,5

2,9

3,9

5,5

8-10

Use of Oxygen Sensors According to Purity Percentages

N2 Purity

97,00%

99,00%

99,50%

99,90%

99,99%

99,999%

Zirconia Sensors

-

-

-

True

True

True

Electrochemical Sensors

True

True

True

-

-

-