30+

Volume

T Series

345 – 730 Nm³/hour

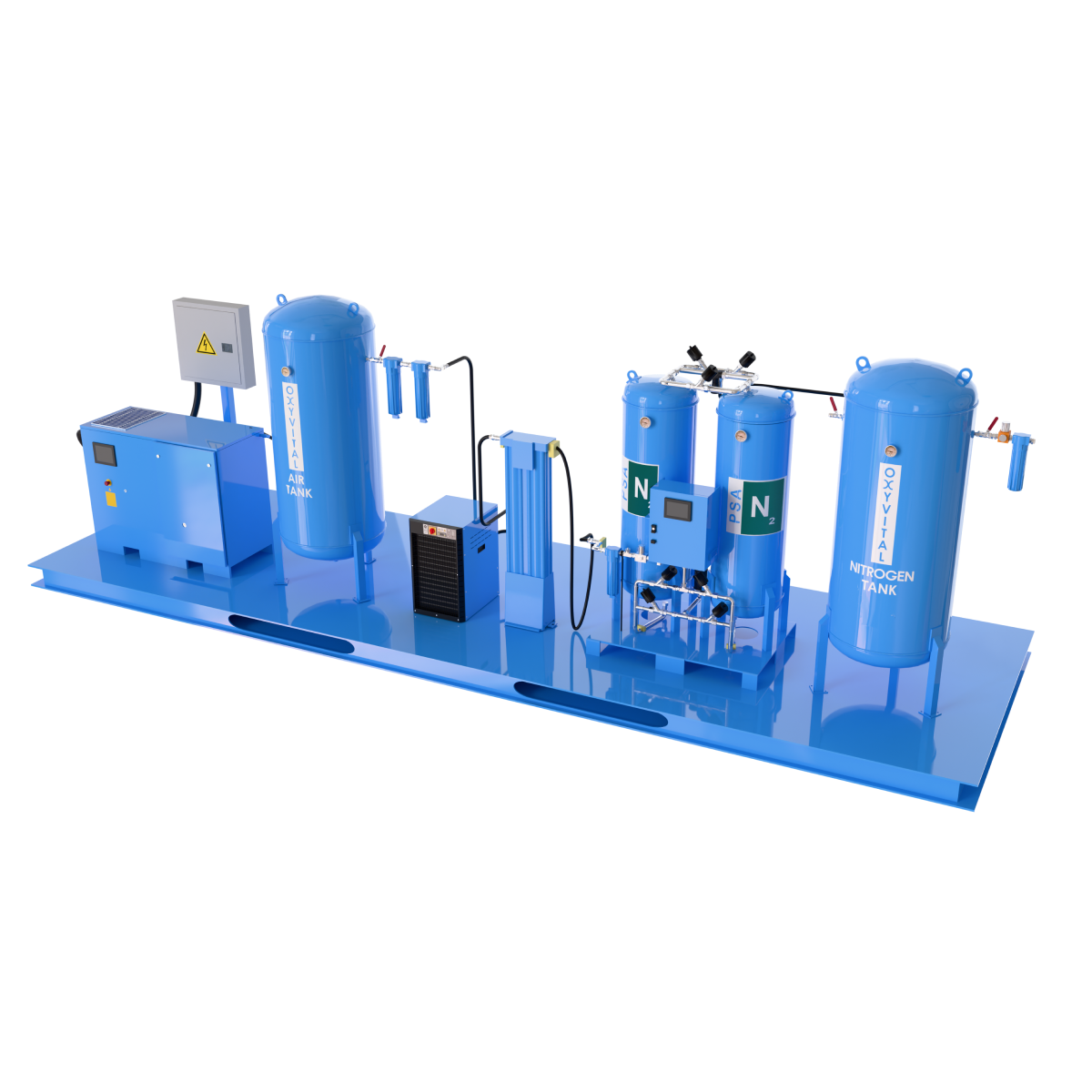

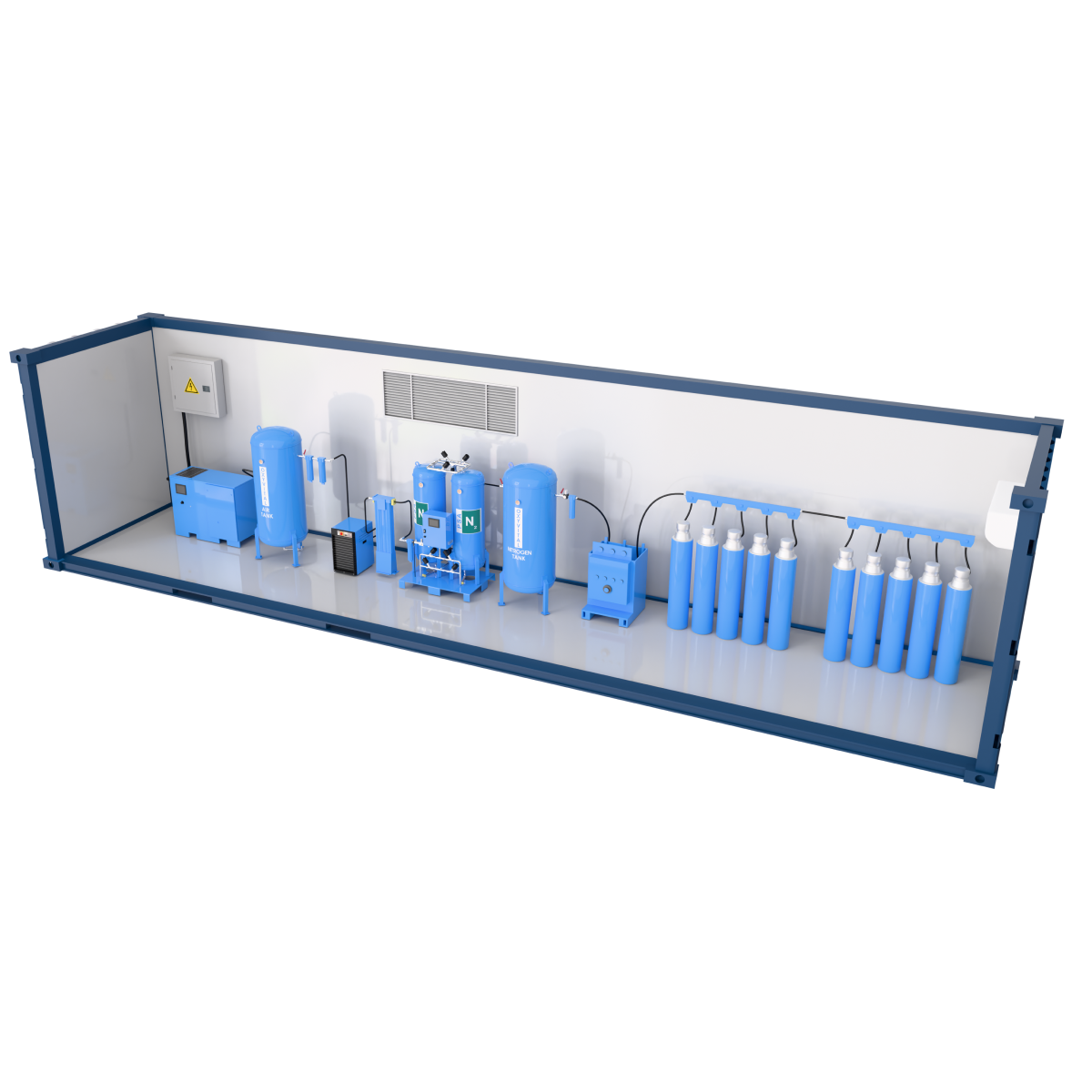

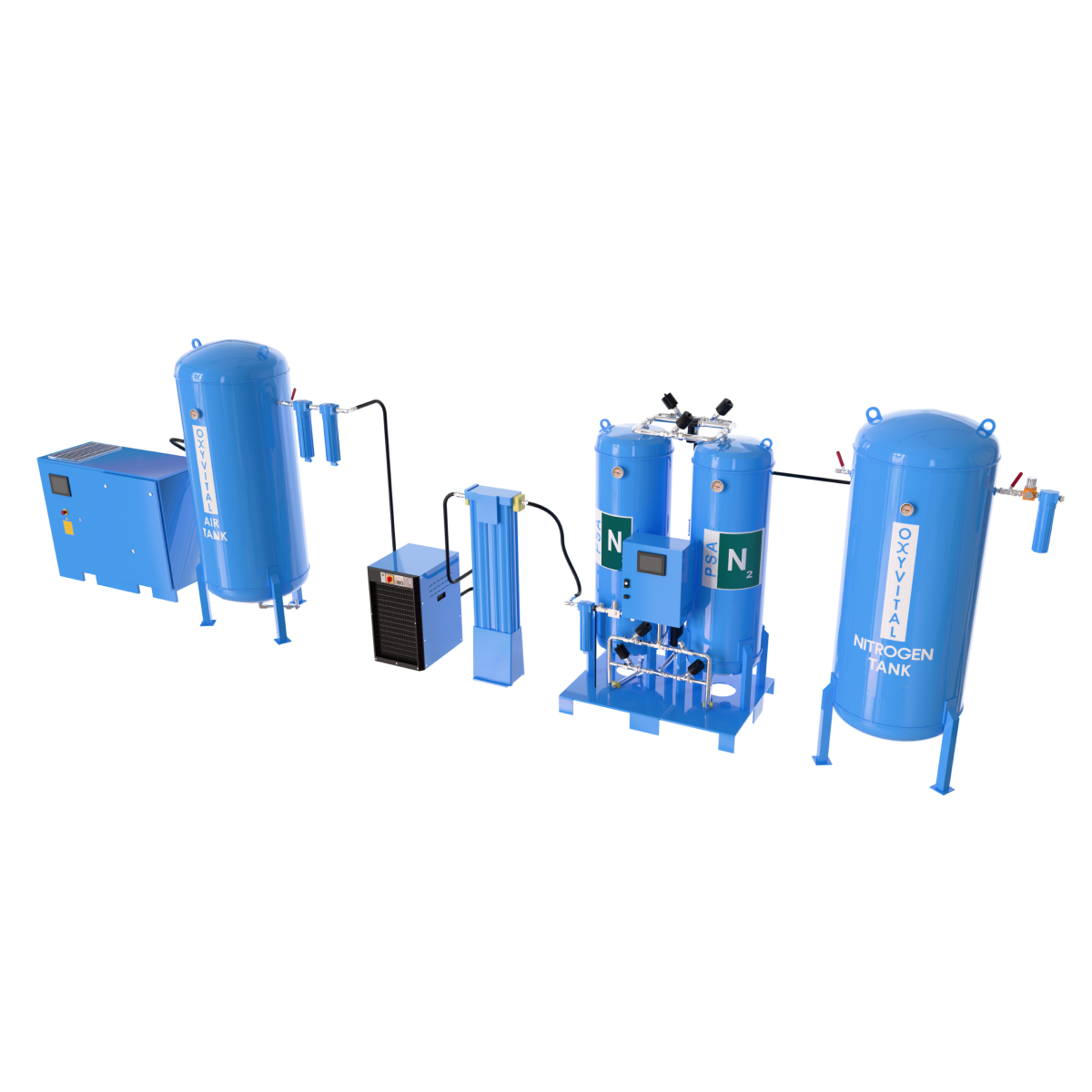

T Series - PSA Nitrogen Generators

Ultra-High Capacity, Maximum Reliability

The OXYN T Series is our most powerful PSA generator series, engineered for industrial facilities with exceptionally high nitrogen demands.

With the capability to deliver up to 730 Nm³/h in a single system and achieve purity levels of up to %99.999, it ensures continuous inert gas production for petrochemical, steel, energy, and large-scale food processing plants.

The T Series guarantees 24/7 operation under heavy industrial conditions, low maintenance requirements, and energy efficiency, ensuring a fast return on investment.

Applications

Petrochemicals and Refineries

Reactor inerting, storage tank blanketing.

Iron & Steel and Metallurgy

Melting, heat treatment, and oxidation prevention.

Food & Beverage

High-volume packaging lines, silo and tank inerting.

Power Plants

Turbine protection, circuit inerting.

Features that Distinguish the T Series from the K Series

Higher capacity (345 – 730 Nm³/h).

Integrated energy-saving mode and automatic load optimization.

Reinforced body and valve system designed exclusively for large-scale industrial complexes.

T Series - PSA Nitrogen Generators

Key Advantages of the T Series

T Series – PSA Nitrogen Generators

OXYN-350

Total Inert Gas Purity

%97

345,0

345,0

%99

303,2

303,2

%99,5

214,6

214,6

%99,9

162,4

162,4

%99,99

95,6

95,6

%99,999

53,9

53,9

Inlet Pressure (bar)

7,5

7,5

Nominal Capacity (Nm³/h)

345,0

345,0

Operating Temperature (°C)

30

30

Technology

PSA (Pressure Swing Adsorption) – Carbon Molecular Sieve (CMS)

PSA (Pressure Swing Adsorption) – Carbon Molecular Sieve (CMS)

Operating Mode

Fully automatic, unmanned operation

Fully automatic, unmanned operation

Control System

Industrial PLC automation, remote monitoring, and data logging system

Industrial PLC automation, remote monitoring, and data logging system

Options

Redundant valve group, energy-saving mode, automatic start/stop

Redundant valve group, energy-saving mode, automatic start/stop

Model Range

OXYN-350, OXYN-420, OXYN-535, OXYN-730

OXYN-350, OXYN-420, OXYN-535, OXYN-730

OXYN-420

Total Inert Gas Purity

%97

421,0

421,0

%99

370,2

370,2

%99,5

262,2

262,2

%99,9

198,7

198,7

%99,99

117,4

117,4

%99,999

66,6

66,6

Inlet Pressure (bar)

7,5

7,5

Nominal Capacity (Nm³/h)

421,0

421,0

Operating Temperature (°C)

30

30

Technology

PSA (Pressure Swing Adsorption) – Carbon Molecular Sieve (CMS)

PSA (Pressure Swing Adsorption) – Carbon Molecular Sieve (CMS)

Operating Mode

Fully automatic, unmanned operation

Fully automatic, unmanned operation

Control System

Industrial PLC automation, remote monitoring, and data logging system

Industrial PLC automation, remote monitoring, and data logging system

Options

Redundant valve group, energy-saving mode, automatic start/stop

Redundant valve group, energy-saving mode, automatic start/stop

Model Range

OXYN-350, OXYN-420, OXYN-535, OXYN-730

OXYN-350, OXYN-420, OXYN-535, OXYN-730

OXYN-535

Total Inert Gas Purity

%97

535,0

535,0

%99

470,2

470,2

%99,5

332,5

332,5

%99,9

251,5

251,5

%99,99

147,8

147,8

%99,999

83,0

83,0

Inlet Pressure (bar)

7,5

7,5

Nominal Capacity (Nm³/h)

535,0

535,0

Operating Temperature (°C)

30

30

Technology

PSA (Pressure Swing Adsorption) – Carbon Molecular Sieve (CMS)

PSA (Pressure Swing Adsorption) – Carbon Molecular Sieve (CMS)

Operating Mode

Fully automatic, unmanned operation

Fully automatic, unmanned operation

Control System

Industrial PLC automation, remote monitoring, and data logging system

Industrial PLC automation, remote monitoring, and data logging system

Options

Redundant valve group, energy-saving mode, automatic start/stop

Redundant valve group, energy-saving mode, automatic start/stop

Model Range

OXYN-350, OXYN-420, OXYN-535, OXYN-730

OXYN-350, OXYN-420, OXYN-535, OXYN-730

OXYN-280

Total Inert Gas Purity

%97

730,0

730,0

%99

641,8

641,8

%99,5

454,3

454,3

%99,9

344,0

344,0

%99,99

202,9

202,9

%99,999

114,7

114,7

Inlet Pressure (bar)

7,5

7,5

Nominal Capacity (Nm³/h)

730,0

730,0

Operating Temperature (°C)

30

30

Technology

PSA (Pressure Swing Adsorption) – Carbon Molecular Sieve (CMS)

PSA (Pressure Swing Adsorption) – Carbon Molecular Sieve (CMS)

Operating Mode

Fully automatic, unmanned operation

Fully automatic, unmanned operation

Control System

Industrial PLC automation, remote monitoring, and data logging system

Industrial PLC automation, remote monitoring, and data logging system

Options

Redundant valve group, energy-saving mode, automatic start/stop

Redundant valve group, energy-saving mode, automatic start/stop

Model Range

OXYN-350, OXYN-420, OXYN-535, OXYN-730

OXYN-350, OXYN-420, OXYN-535, OXYN-730

Required Compressed Air Calculation

N2 Purity

97

99

99,5

99,9

99,99

99,999

Air Factor

2,1

2,5

2,9

3,9

5,5

8-10

Use of Oxygen Sensors According to Purity Percentages

N2 Purity

97,00%

99,00%

99,50%

99,90%

99,99%

99,999%

Zirconia Sensors

-

-

-

True

True

True

Electrochemical Sensors

True

True

True

-

-

-