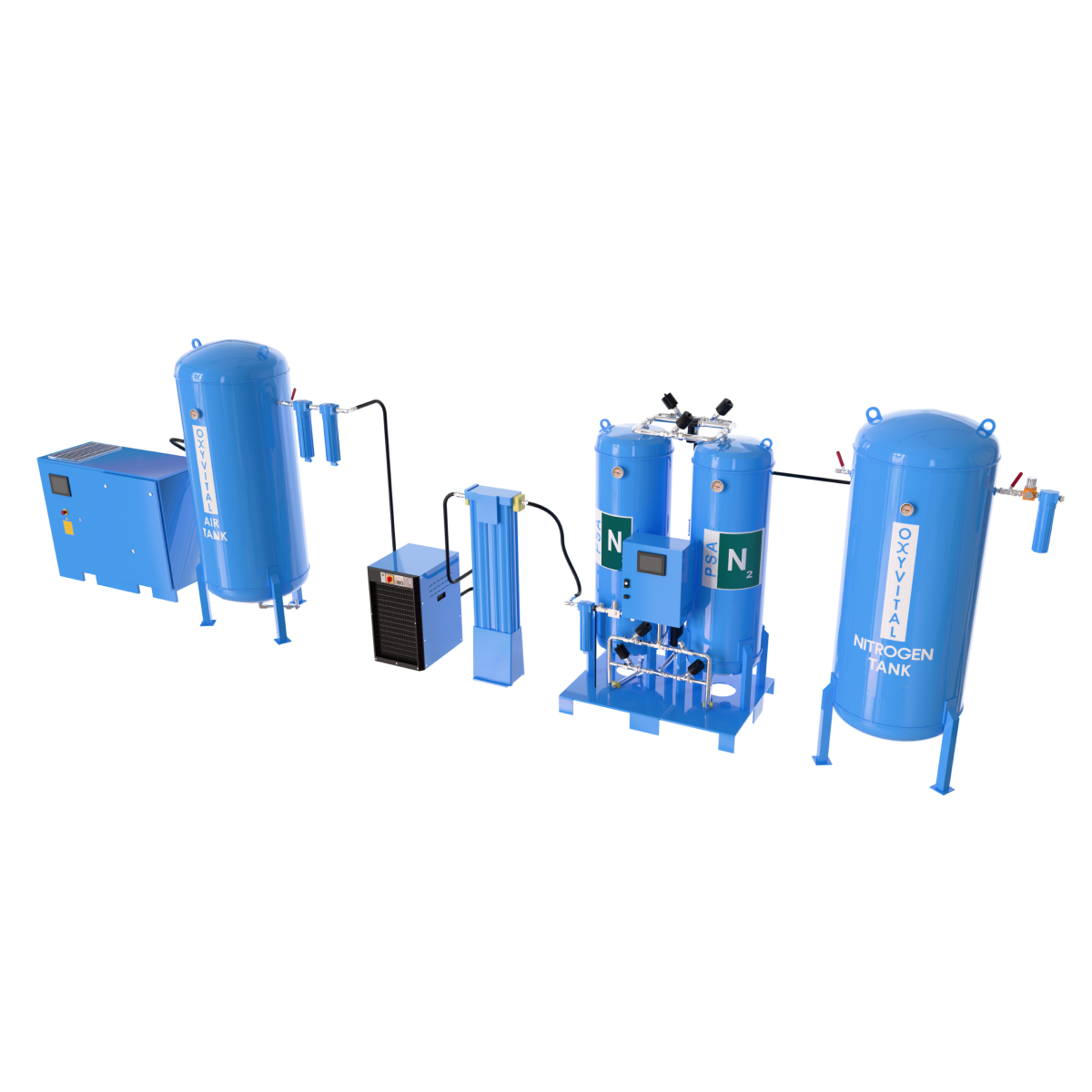

Use of OXYVITAL PSA Nitrogen Generators in Beverage Production

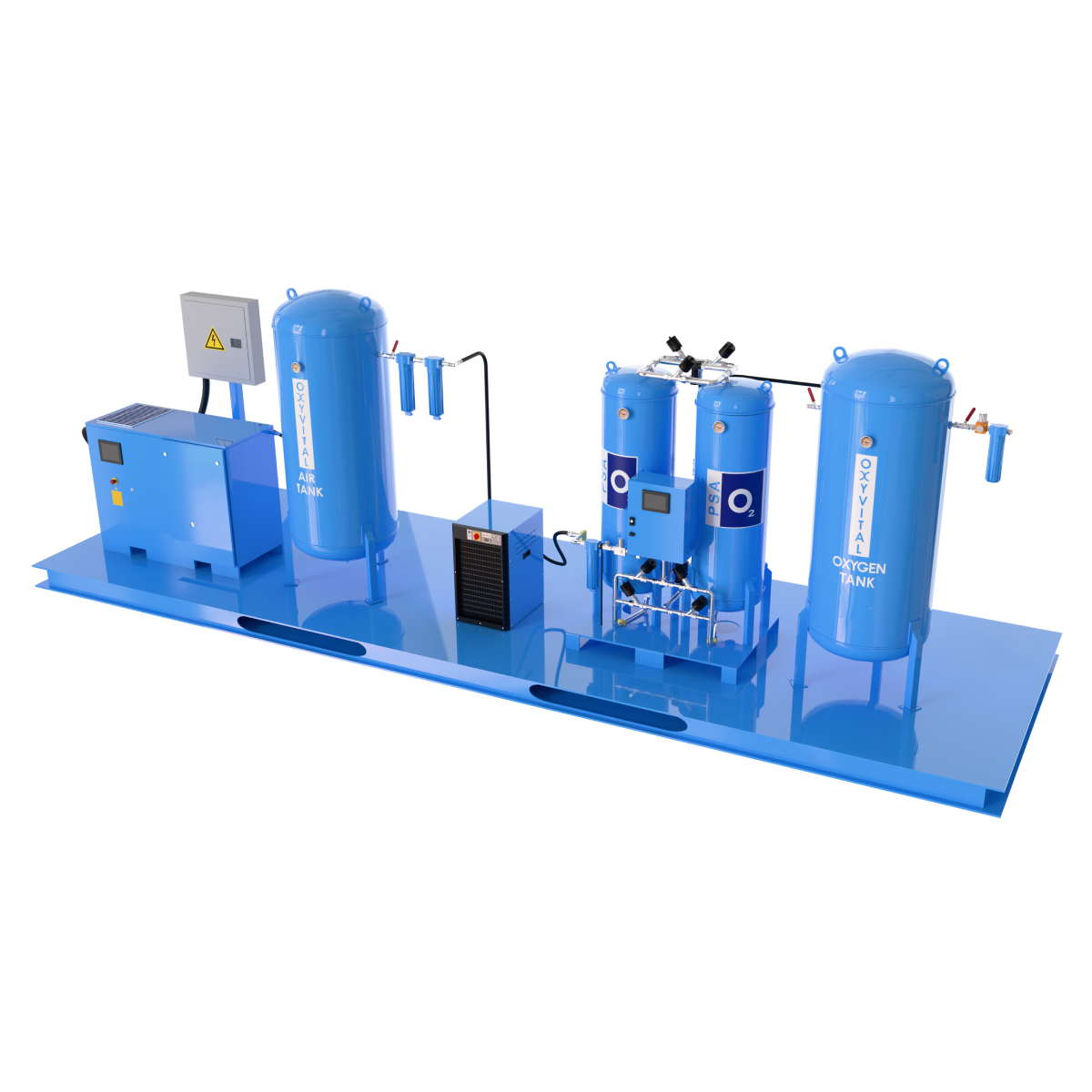

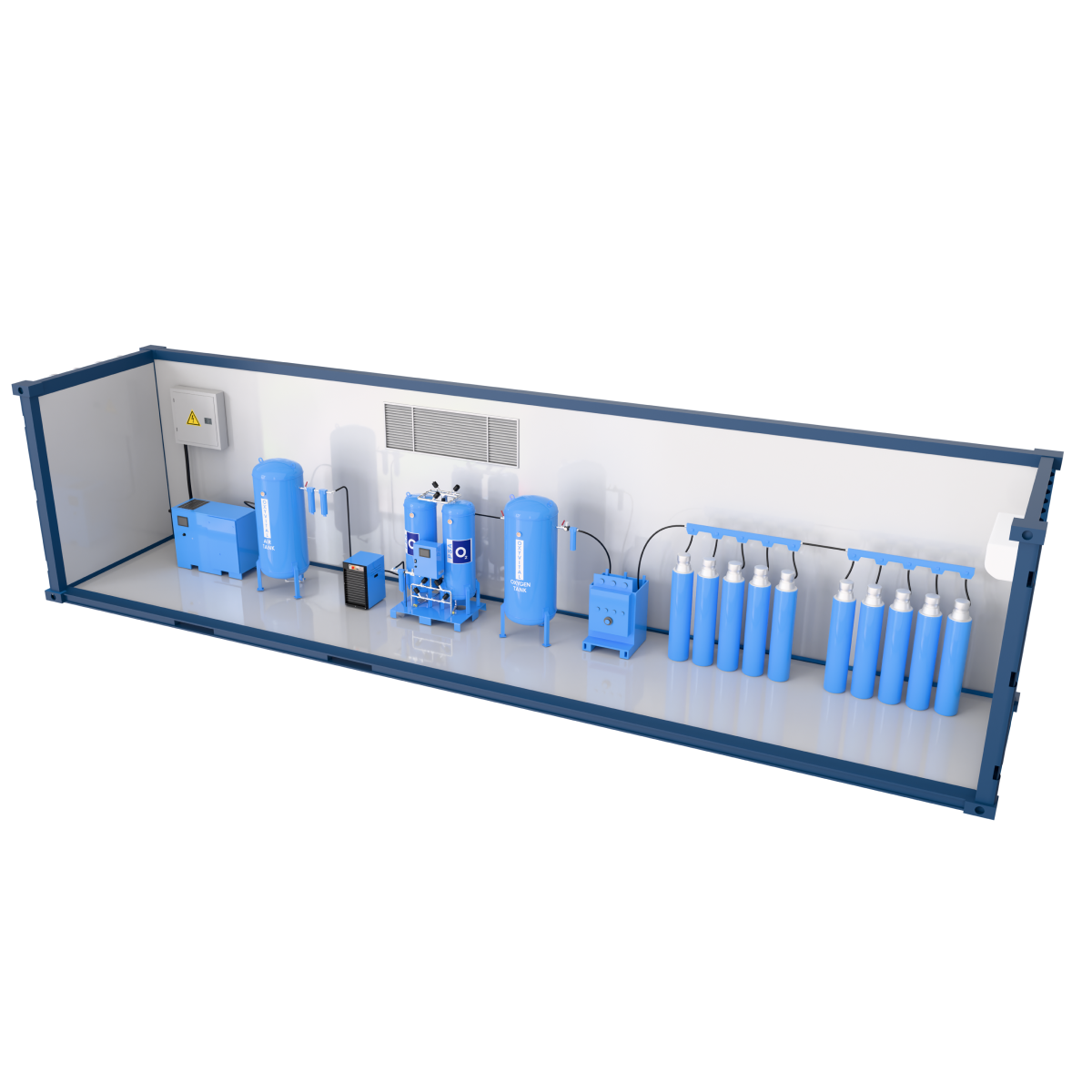

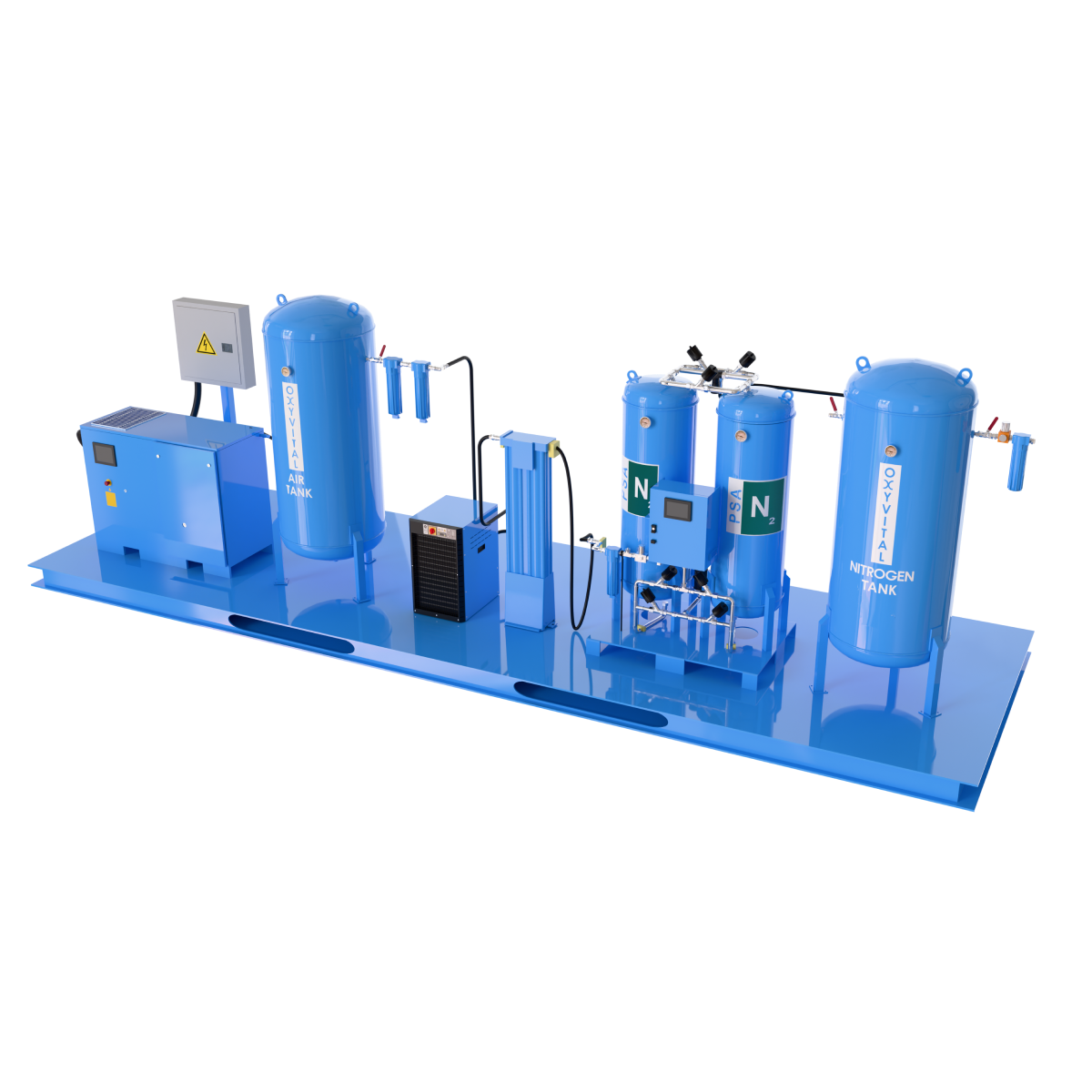

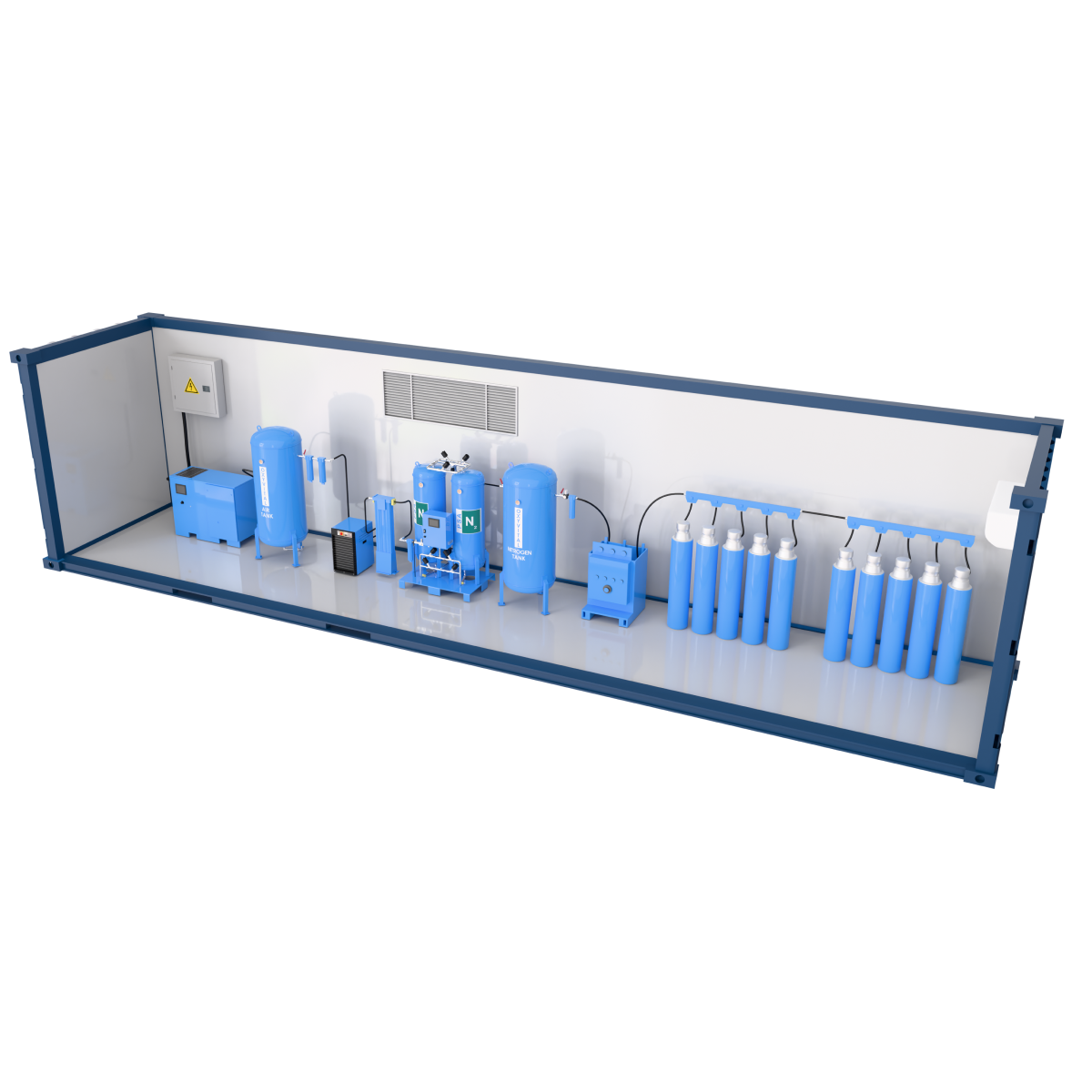

In beverage production, nitrogen (N₂) is widely used to prevent oxidation, preserve flavor, stabilize carbonation, and enhance packaging durability. OXYVITAL PSA Nitrogen Generators provide beverage plants with a continuous, high-purity, and cost-effective nitrogen supply, optimizing production processes.

Applications of PSA Nitrogen Generators in Beverage Production

1. Wine and Beer Production

Reduces oxygen contact in wine and beer production, preventing oxidation.

Using nitrogen in wine barrels and tanks prevents flavor degradation and ensures long-lasting freshness.

In beer production, lowering oxygen levels after fermentation extends shelf life and preserves taste profile.

2. Fruit Juices and Herbal Drinks

Prevents oxidation in fruit juices, preserving vitamins and antioxidants.

Maintains the natural taste of citrus juices, detox beverages, and herbal extracts for longer periods.

3. Carbonated and Sparkling Beverages

Nitrogen is used during bottling to prevent CO₂ loss in carbonated drinks.

Improves foam stability, keeping sparkling beverages fresh for longer.

Ensures packaging stability in energy drinks, soda, and mineral water production.

4. Cold Tea and Coffee Production

In nitro coffee (Nitro Cold Brew) production, nitrogen gives the beverage a creamy texture.

Prevents color and flavor degradation in cold teas by eliminating oxygen contact.

Extends shelf life by keeping packaging oxygen-free.

5. Packaging and Bottling Processes

Replaces oxygen with nitrogen in bottles, cans, and cartons, preventing package swelling.

Enables low-pressure bottling, increasing beverage shelf life.

In PET and glass bottles, nitrogen prevents product damage during transportation.

Advantages of OXYVITAL PSA Nitrogen Generators in Beverage Production

Extends the shelf life of wine, beer, and fruit juices by reducing oxygen exposure.

Preserves carbonation in sparkling beverages, enhancing flavor and texture stability.

Prevents taste deterioration during bottling and packaging by replacing oxygen.

Provides natural preservation without the need for chemical additives.

Reduces production costs with a continuous supply of high-purity nitrogen.

Eliminates reliance on oxygen cylinders and liquid nitrogen deliveries, lowering logistics and operating expenses.

OXYVITAL PSA Nitrogen Generators make beverage production safer, more economical, and more efficient by minimizing oxygen exposure throughout the process.