PSA Nitrogen Generators

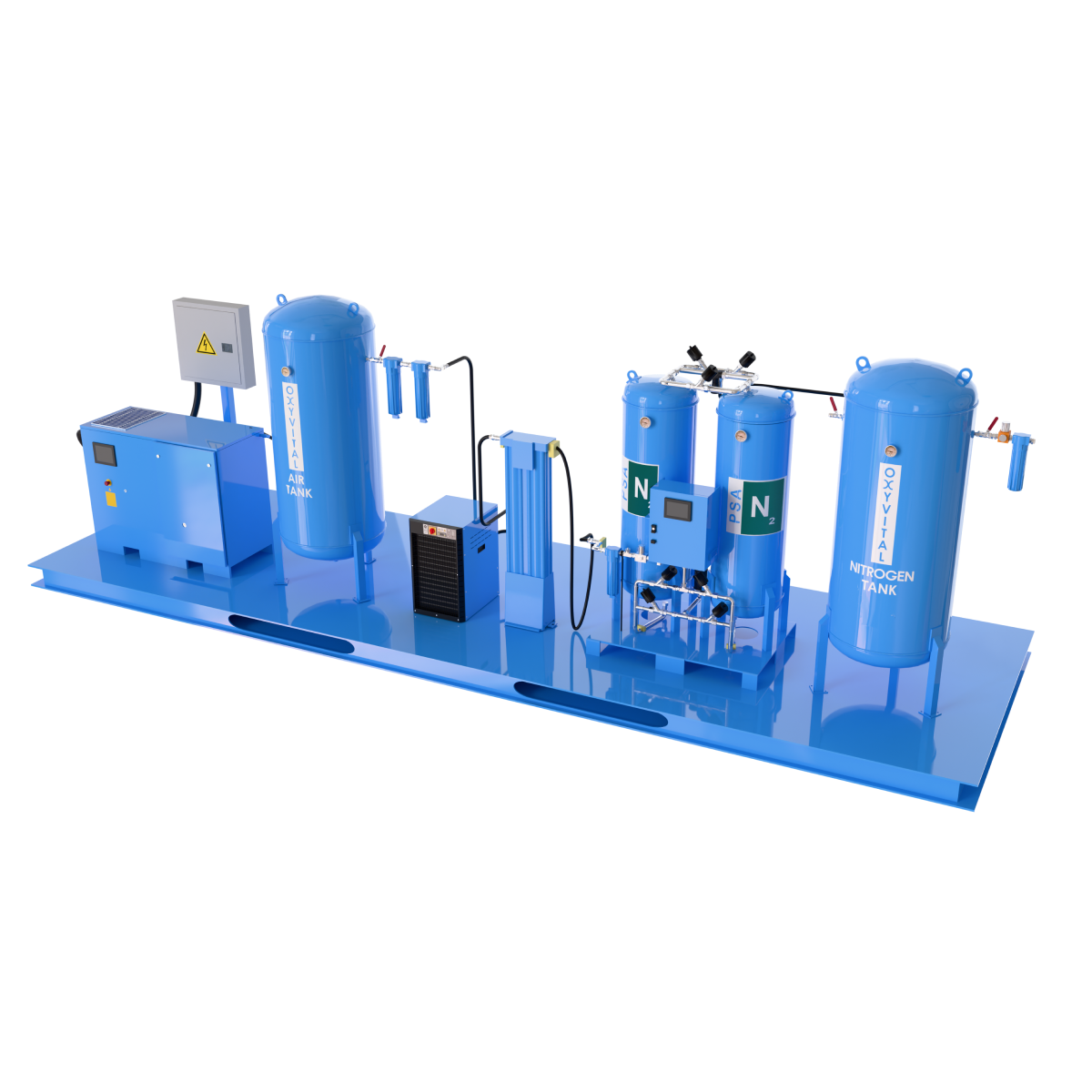

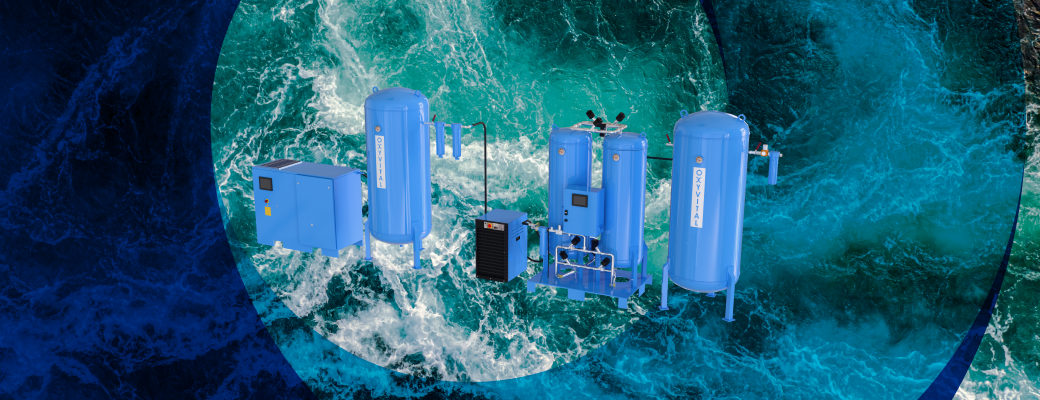

Cut your industrial gas costs and elevate your efficiency to the peak. Designed with Oxyvital’s 46+ years of experience, our PSA nitrogen generators save your business from the risks of the cylinder and liquid nitrogen supply chain. From laser cutting to food packaging, from electronics to the chemical sector, produce the nitrogen you need on-site with our advanced nitrogen generation systems.

Oxyvital PSA N₂ Generator Models and Series

Discover our range of nitrogen generators that perfectly match your facility’s production capacity and purity demands. We offer a wide spectrum of solutions, from small-scale workshop units to large-scale industrial nitrogen generator plants. Take control of your gas costs with nitrogen generation systems capable of producing purities ranging from 95% up to 99.999%.

Why Should You Use a PSA Nitrogen Generator?

End Liquid and Cylinder Gas Dependency, Produce On-Site

Instead of purchasing gas externally, switch to an on-site nitrogen generator model to eliminate logistics, rental, and transportation costs. PSA nitrogen generator technology gives your business the freedom to produce the exact amount of gas needed, exactly when it is needed, without supply chain interruptions.

Savings That Quickly Cover the Investment Cost

Don't be affected by constantly rising gas unit prices. Although the nitrogen generator price may seem like an initial capital expense, the system amortizes itself in a very short time compared to purchasing liquid or bulk gas. Oxyvital N2 generator solutions increase your profitability with low operating costs.

ISO Certified Assurance from Turkey’s First Manufacturer

Work with the engineering power that creates the technology, not just a supplier. As Turkey's first manufacturer, Oxyvital represents 46 years of accumulated knowledge among nitrogen generator manufacturers. With thousands of references, we install nitrogen generator systems that run uninterrupted even under the most challenging industrial conditions.

Sustainable and Continuous Industrial Gas Flow

Your production line should never stop. Thanks to our dual-tank and redundant PSA nitrogen gas generators, a 7/24 continuous gas flow is ensured. Integrated directly into your compressed air line, our systems completely eliminate production losses caused by external supply delays.

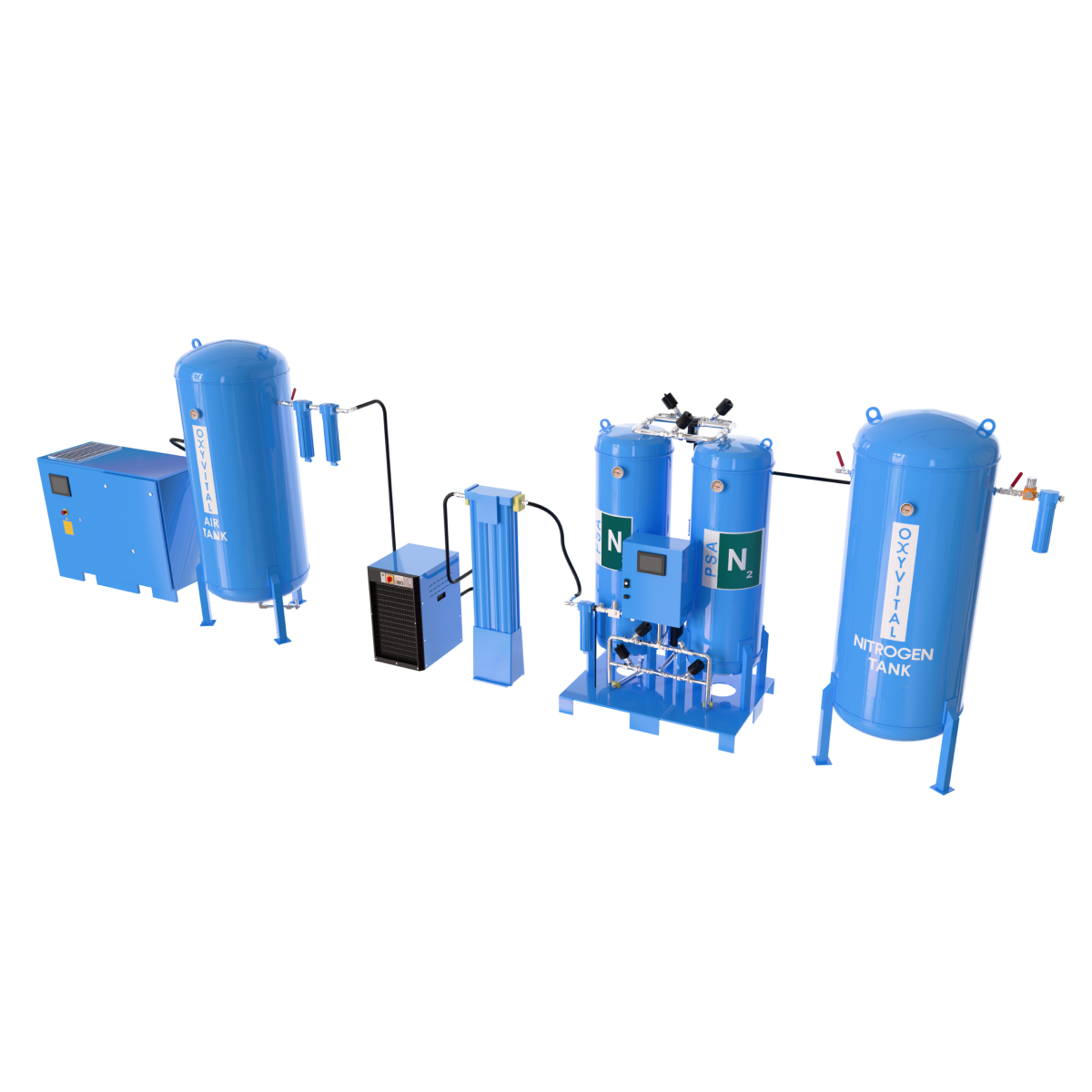

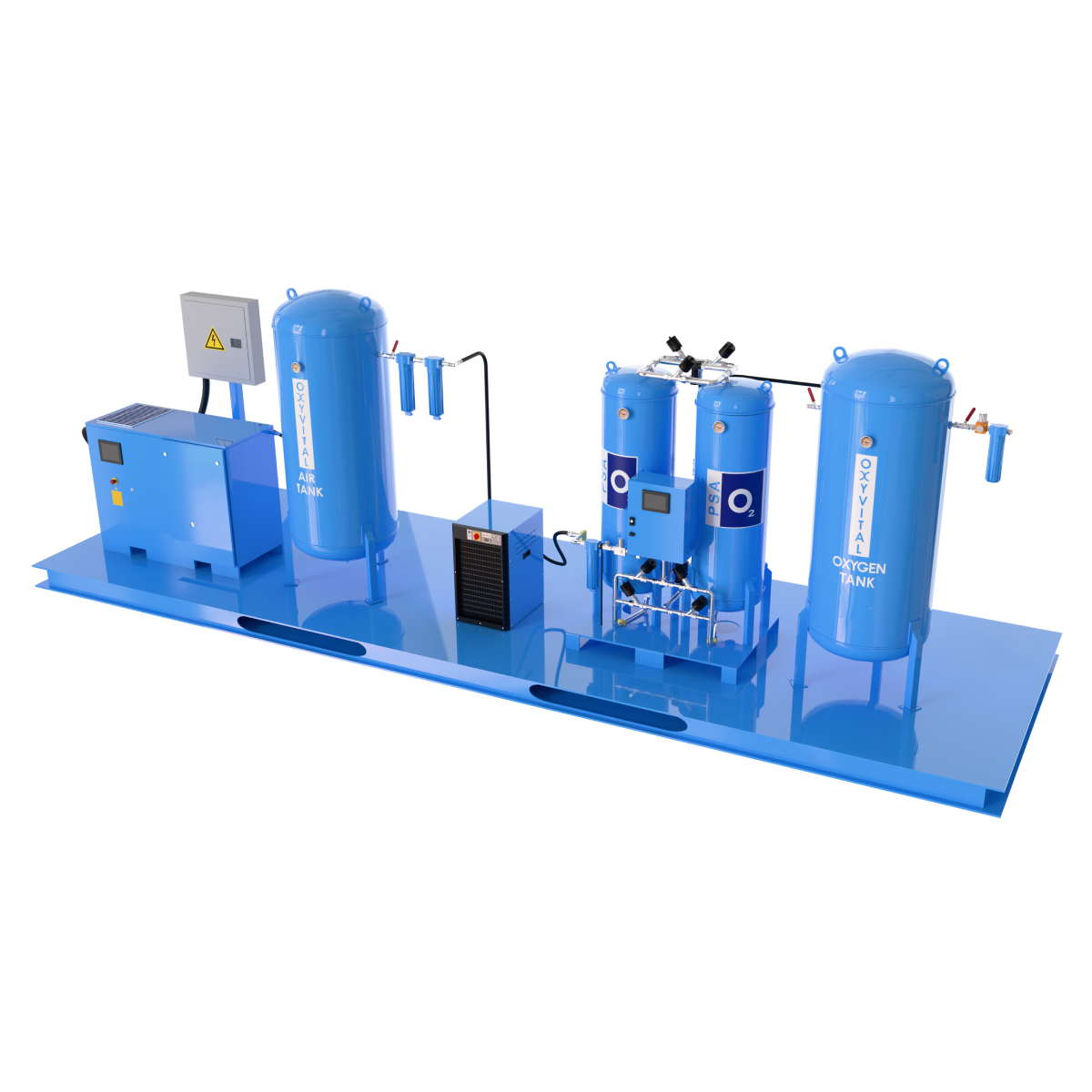

In Oxyvital PSA nitrogen generators, the process begins with ambient air being drawn into the system via a compressor and passed through pre-filters to remove moisture, oil, and particles. The clean air is directed under pressure into tanks filled with Carbon Molecular Sieve (CMS). Here, the CMS material adsorbs oxygen molecules while releasing high purity nitrogen.

Thanks to the dual-tank design in the pressure swing adsorption nitrogen generation process, while one tank is producing, the other depressurizes to release the trapped oxygen and regenerate itself (desorption). This alternating operation guarantees continuous nitrogen gas generation for your business.

Benefits of On-Site Nitrogen Production with Oxyvital

Developed specifically for your application requirements, our PSA nitrogen generators offer long life and maximum efficiency with high-quality CMS technology. Oxyvital provides lasting solutions that add value to your business with international manufacturing standards.

On-Site Production: Offers the ability to generate nitrogen directly at your facility. With onsite nitrogen gas generation, you avoid extra operational costs and time losses associated with logistics, transport, and cylinder supply.

High Purity Guarantee: Never leave gas quality to chance in critical industrial applications. Our nitrogen gas generators offer precise purity guarantees starting from 95% up to high purity nitrogen generator levels of 99.999%.

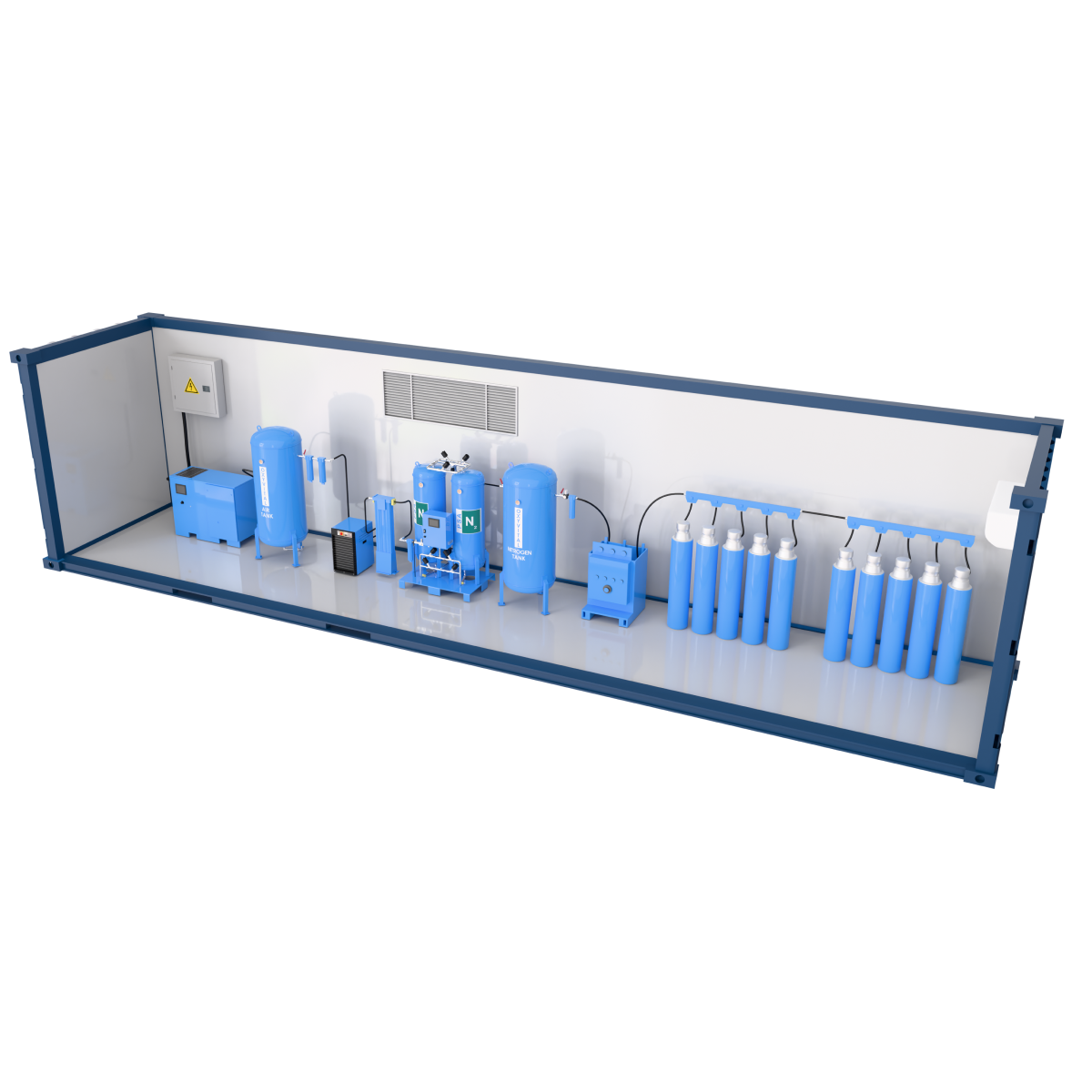

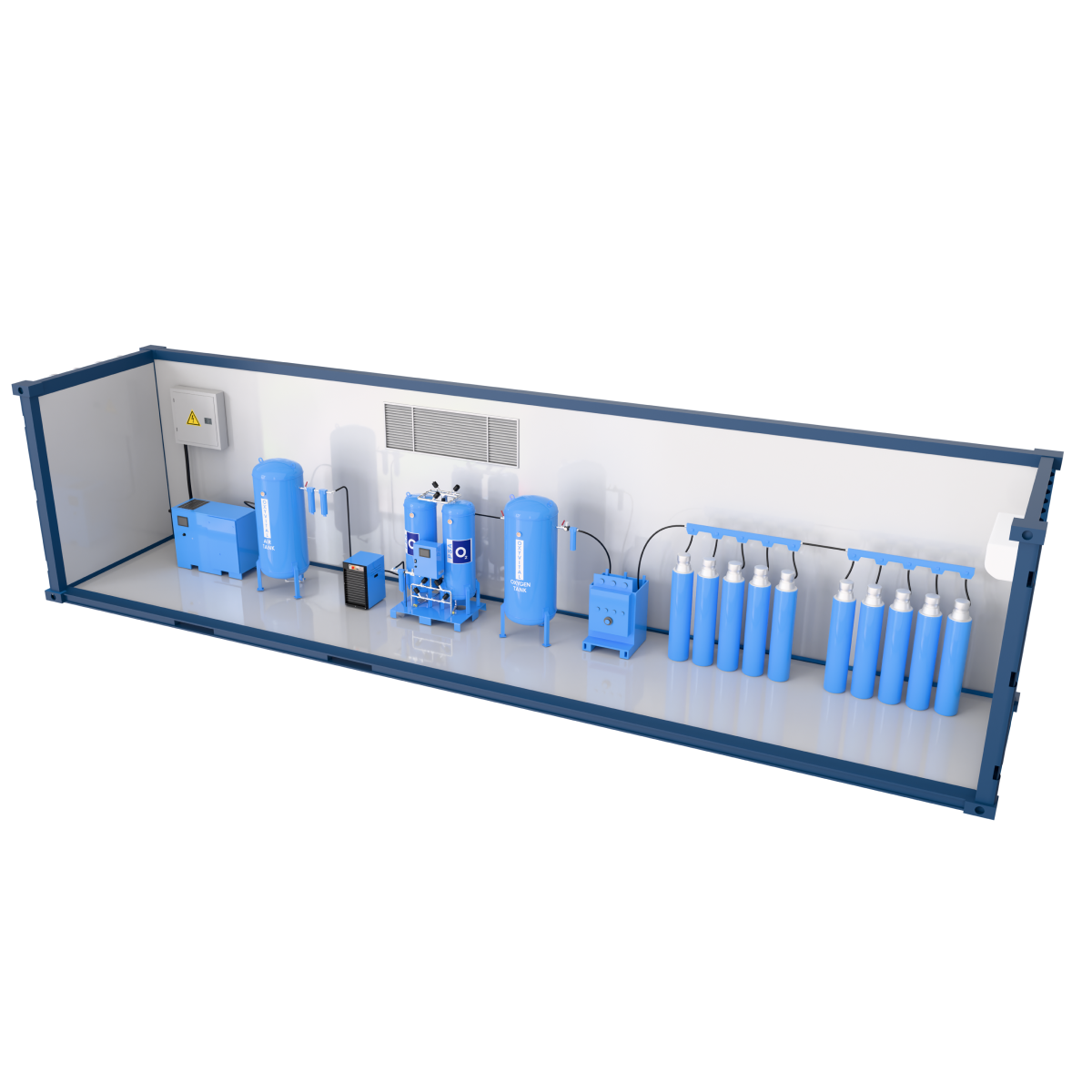

Modular and Mobile Solutions: Adapts to your business growth goals. Scalable, modular, or portable nitrogen generation systems can be designed according to different capacities and usage scenarios.

Uninterrupted Gas Supply: Unaffected by disruptions in the external supply chain. With 7/24 continuous operation, it ensures total continuity in gas supply for your production line.

Low Operating Cost: Efficient PSA technology combines low electricity consumption with minimum maintenance requirements, ensuring the nitrogen generator for sale investment pays for itself quickly.

High Safety: Eliminates the risks associated with storing high-pressure cylinders. Advanced automatic control systems and safety sensors always prioritize user safety.

Easy Integration: Designed for plug-and-play. It works in full compatibility with your existing compressed air systems and compressor infrastructure, shortening the integration process.

Long-Lasting Performance: LWith a chassis resistant to harsh industrial conditions, high-quality valves, and a durable CMS structure, the system provides stable and uninterrupted service for many years.

Industrial and Medical Application Areas

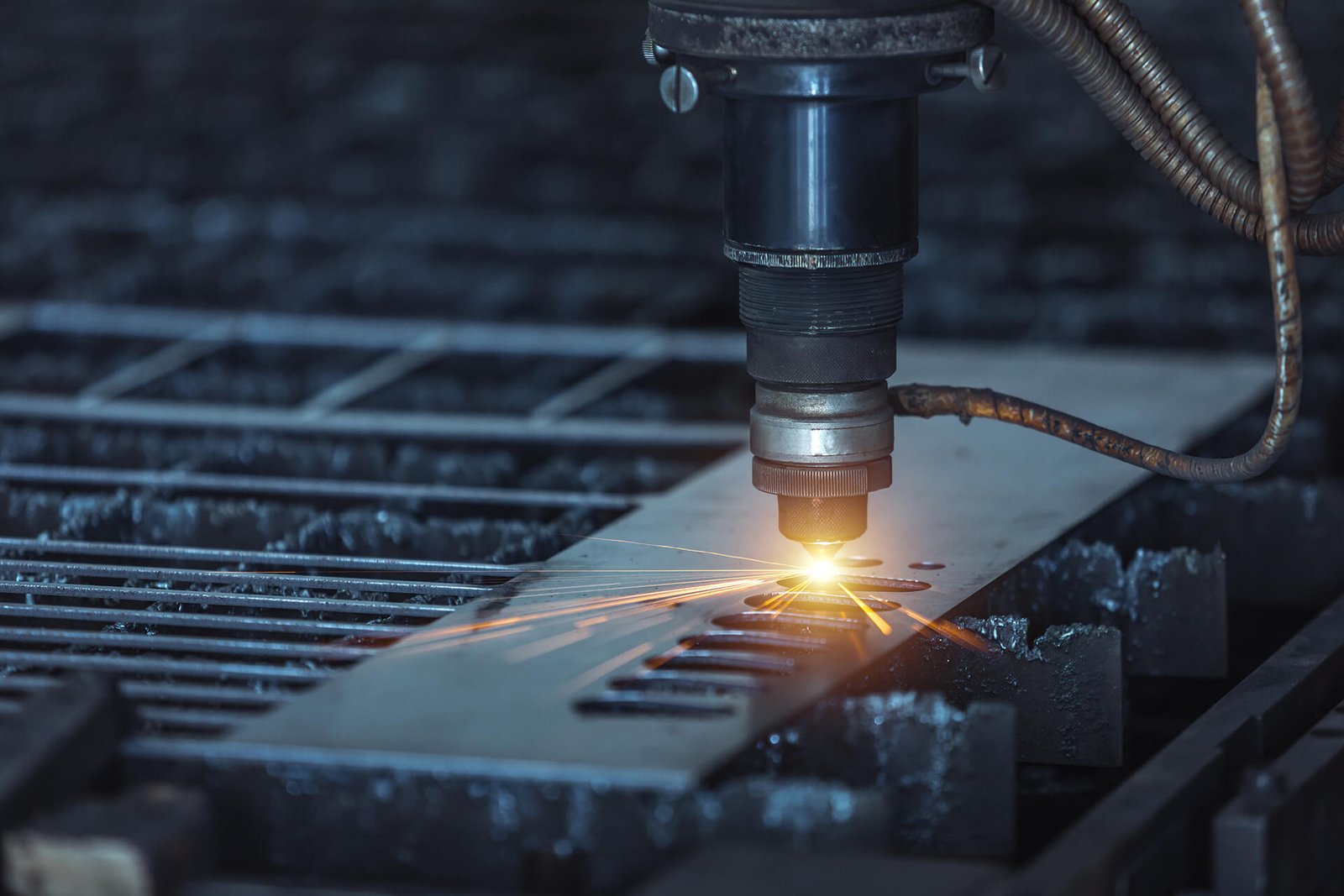

Oxyvital nitrogen generators adapt fully to the changing purity and pressure requirements of the industry. They have a wide range of uses, from high pressure nitrogen generator applications in laser cutting lines to food packaging (MAP) processes, and from compact lab-type systems to large-scale nitrogen generation plant installations.

Use of OXYVITAL PSA Nitrogen Generators for Controlling Flammable and Explosive Reactions

Use of OXYVITAL PSA Nitrogen Generators in Laser and Plasma Cutting

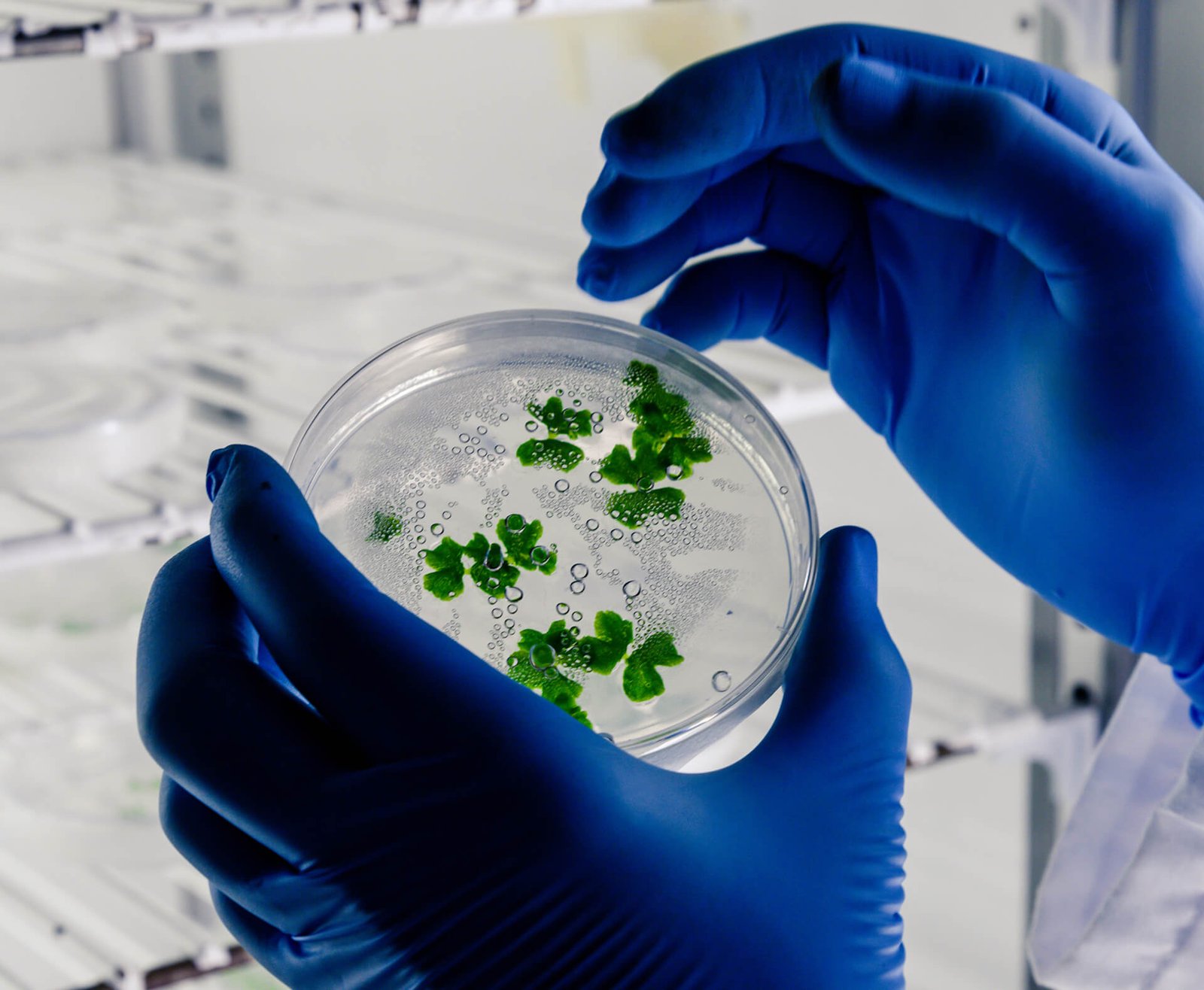

Use of OXYVITAL PSA Nitrogen Generators in Biological Sample Storage